A technical pack is an essential document in the fashion industry that serves as a comprehensive blueprint for creating a garment.

It outlines all specifications and design details needed to ensure that the final product meets the designer’s vision and quality standards.

A well-prepared tech pack can significantly streamline communication between designers and manufacturers, leading to more efficient production and fewer costly errors.

These documents typically include technical sketches, a bill of materials, size specifications, and even details on colorways and artwork.

Each component plays a vital role in conveying the necessary information for seamless production.

Designers who utilize tech packs often find that they reduce the number of sampling rounds, saving both time and money.

For anyone looking to thrive in the competitive fashion market, understanding and implementing a technical pack is crucial.

Armed with the right tools and knowledge, designers can enhance their workflow and bring their creative concepts to life more effectively.

Purpose of a Technical Pack

A technical pack serves multiple essential functions in the garment production process.

It streamlines communication, ensures quality control, and minimizes production errors.

Each of these elements contributes to a more efficient workflow and a higher-quality finished product.

Communication with Manufacturers

Effective communication is crucial in the fashion industry.

A technical pack acts as a comprehensive guide for manufacturers, detailing every aspect of the design.

This includes technical specifications, materials, and construction methods.

Providing explicit information mitigates misunderstandings.

Clear illustrations, such as technical drawings, help visualize the design intent, ensuring that manufacturers correctly interpret the designer’s vision.

A well-structured technical pack leads to a smoother collaboration, fostering confidence between designers and manufacturers.

With this clarity, both parties can align their expectations effectively.

Quality Control and Consistency

Quality control is vital for maintaining brand integrity.

A technical pack outlines specific quality standards that a finished garment must meet.

This includes fabric types, color specifications, and construction techniques.

By documenting these criteria, it becomes easier to maintain consistency across production runs.

Manufacturers can refer back to the technical pack at different stages, ensuring they adhere to the original design intentions.

This proactive approach to quality helps prevent defects and variations.

Establishing these standards also makes it easier to address issues, as both parties will have a clear reference point.

Reducing Production Errors

Reducing production errors can save significant time and money.

A comprehensive technical pack minimizes the chance of mistakes during manufacturing.

Detailed descriptions of each component, including sizes and finishes, leave little room for ambiguity.

When all specifications are documented, manufacturers can produce garments that closely match the designer’s vision.

This accuracy leads to fewer samples, revisions, and ultimately, lower costs.

Incorporating visual aids, such as charts and lists, within the technical pack further clarifies expectations.

By doing so, the likelihood of miscommunication diminishes, resulting in a more efficient production process.

Components of a Technical Pack

A technical pack is essential for conveying all required specifications for a product.

Key components include technical drawings, a bill of materials, graded measurement specs, construction details, and color and print specifications, each playing a vital role in the production process.

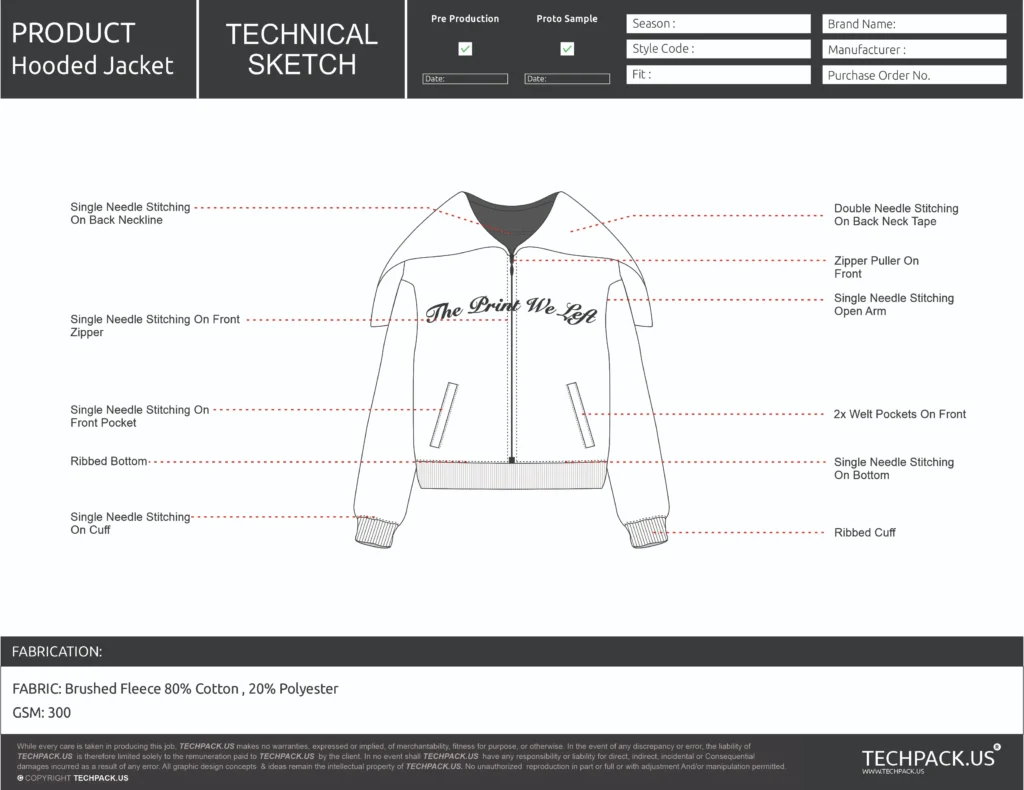

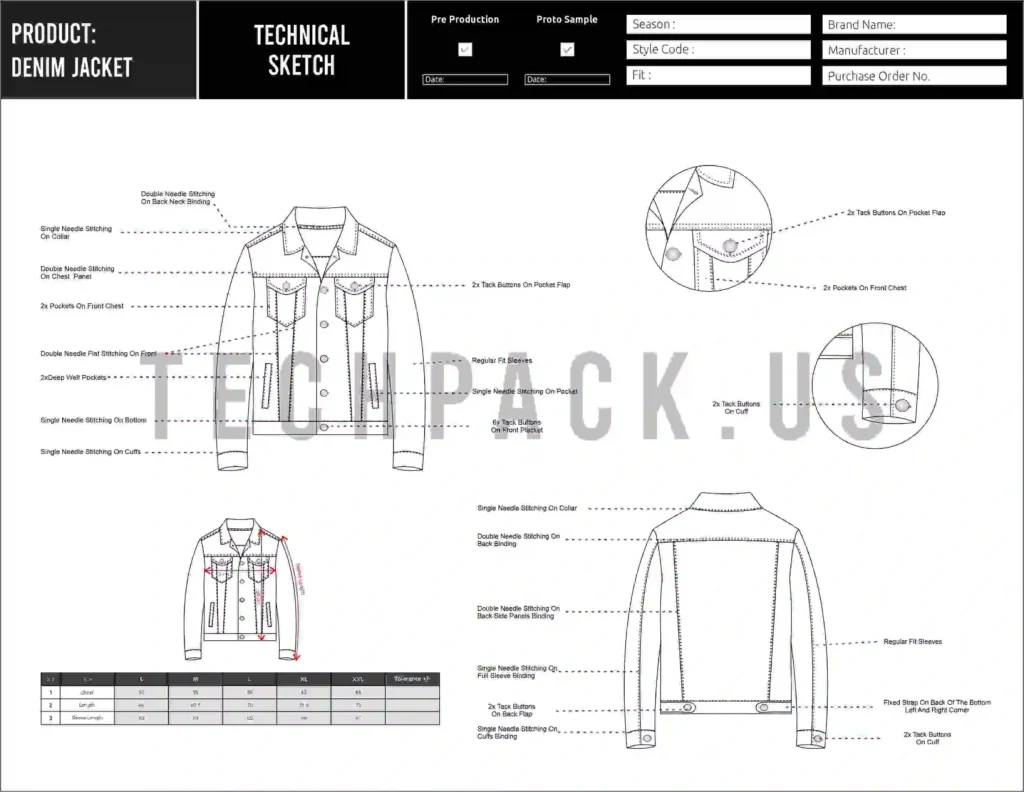

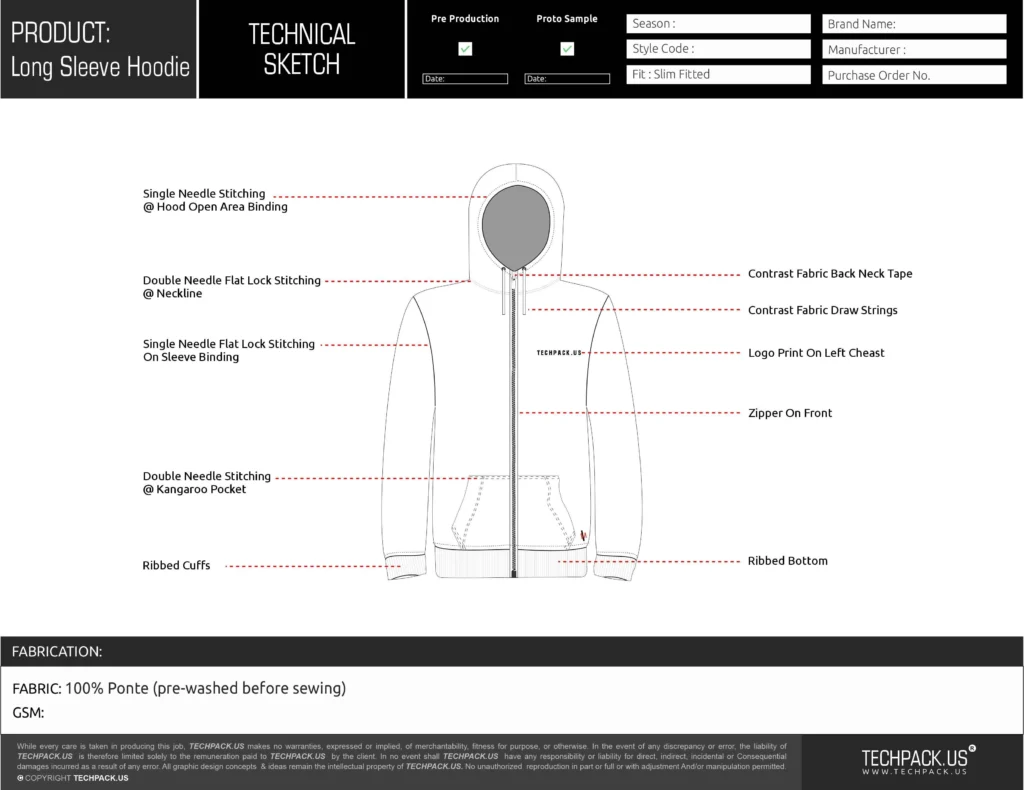

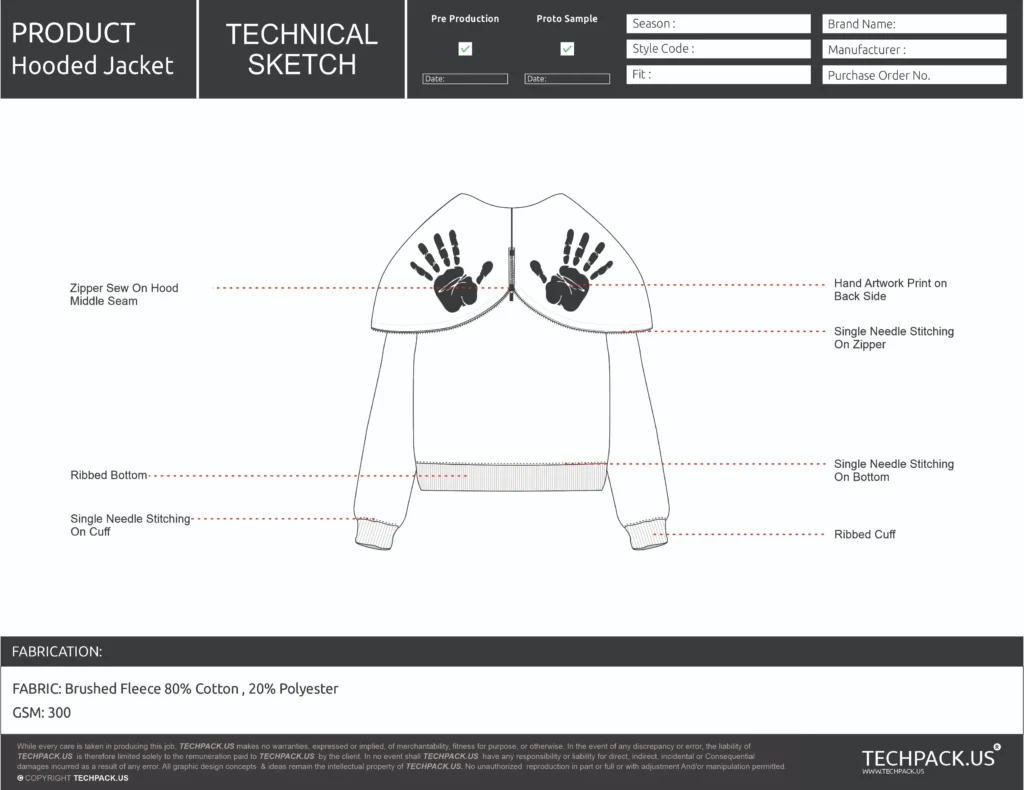

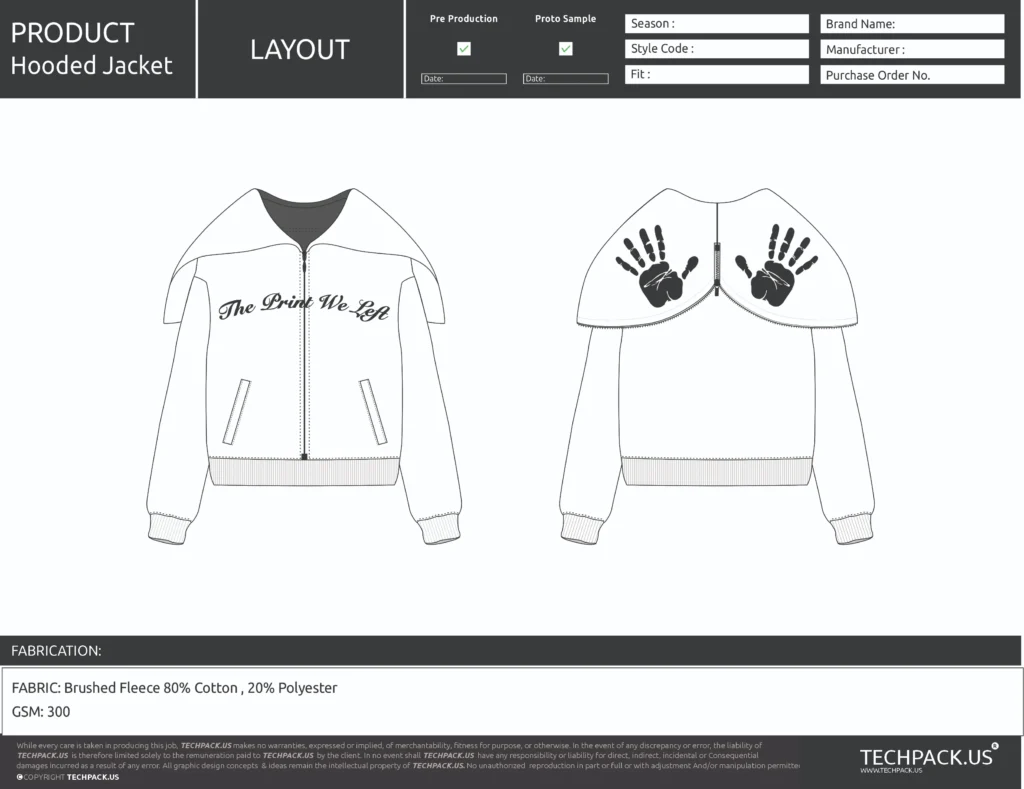

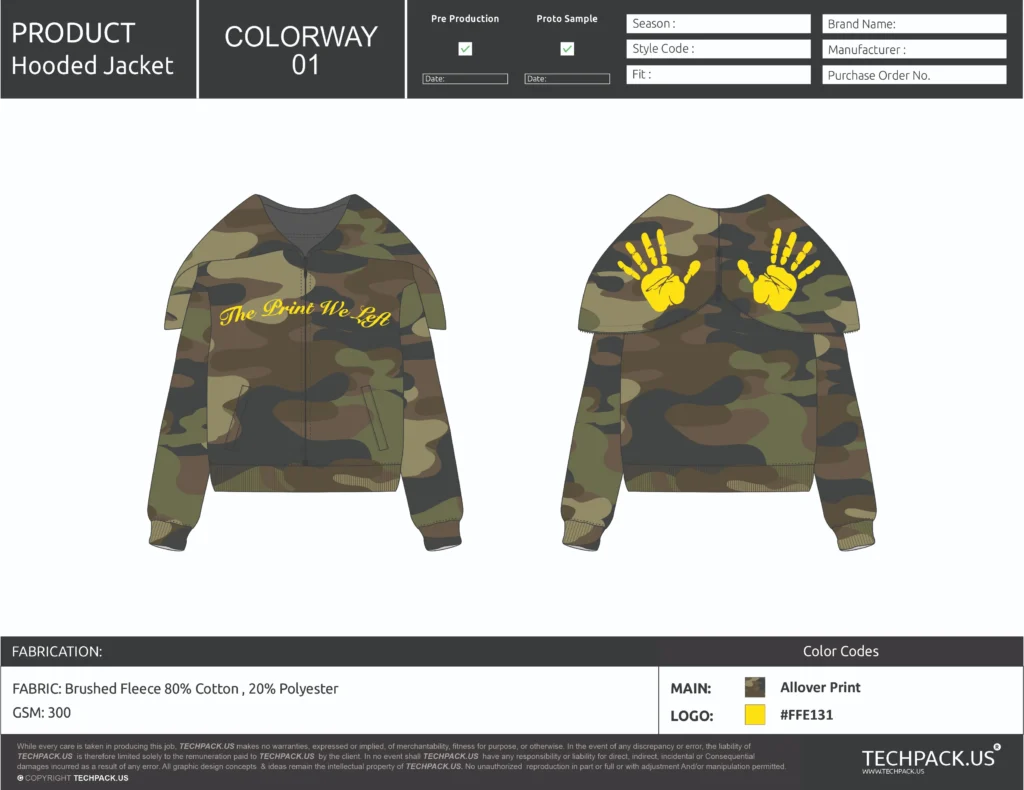

Technical Drawings

Technical drawings serve as visual representations of the garment, providing critical details.

These include flat sketches depicting front and back views and detailed illustrations highlighting specific design elements.

Layers, stitching methods, and dimensions are illustrated to guide manufacturers accurately.

These drawings should include information on pocket placements, seams, and any unique design features that distinguish the garment.

A clear and precise visual will minimize errors during production.

Bill of Materials (BOM)

The Bill of Materials outlines all materials needed to create the garment.

This document includes specifications for fabrics, trims, labels, and any additional components.

For each item, pertinent details such as fabric type, weight (e.g., GSM for fabrics), and color codes are specified.

This level of detail ensures that manufacturers procure the correct materials, reducing delays and costs.

A well-structured BOM is crucial for maintaining quality and consistency.

Graded Measurement Specs

Graded measurement specifications detail how a garment should be sized across different sizes.

This section includes a size chart and critical measurements for each size iteration, ensuring proper fit.

Important metrics include bust, waist, hip, and inseam measurements, alongside any ease allowances required.

Clear grading rules define how dimensions change from one size to another, which is particularly important for ensuring that all variants maintain the intended fit and silhouette.

Construction Details

Construction details provide guidelines on how to assemble the garment.

This section includes instructions on stitching types, finishing techniques, and assembly order.

Manufacturers rely on this information to achieve the required quality standards.

Specific notes on any complex construction methods, such as pleating or lining techniques, are beneficial.

These details ensure consistency in the end product and help mitigate production issues.

Color and Print Specifications

Color and print specifications delineate the exact colors and patterns required for the garment.

This segment often includes Pantone color codes for accurate reproduction.

It covers print placement, scale, and any required printing techniques.

Clear specifications here are crucial for maintaining brand standards and ensuring that the manufacturer replicates the designer’s vision accurately.

Any variations in color or print must be documented meticulously to avoid discrepancies during production.

Creating a Technical Pack

Establishing a comprehensive technical pack involves meticulous preparation and the right tools.

It requires gathering essential information, utilizing appropriate software, and collaborating effectively with designers and technicians.

Each of these elements plays a crucial role in ensuring accuracy and clarity in garment production.

Gathering Necessary Information

The foundation of a technical pack is detailed information.

Key elements include technical sketches, construction details, fabric types, and measurements.

Designers should compile a Bill of Materials (BOM) that lists all materials required for the product, including fabrics, trims, and labels.

It’s vital to define the Point of Measure (POM) accurately.

This aids production teams by providing exact dimensions and specifications, minimizing errors.

By collecting accurate data from the outset, you streamline the production process and mitigate potential issues.

Collaboration with Designers and Technicians

Effective collaboration is vital when creating a technical pack.

Designers should engage with technical designers and pattern makers from the beginning.

Open communication about design intentions and nuances can prevent misunderstandings later in the process.

Regular meetings to review the tech pack help ensure that everyone is aligned.

Input from technicians regarding construction feasibility is crucial.

They can provide insights into potential challenges during the production phase.

Utilizing collaborative tools like Slack or Trello can keep all team members connected.

Difference between tech pack and technical pack

The terms “tech pack” and “technical pack” refer to the same document.

They are often used interchangeably in the fashion and apparel industry.

A tech pack serves as a comprehensive guide for manufacturers.

It contains all the necessary details for producing a garment, including materials, measurements, and construction methods.

A technical pack is a formal term that emphasizes the technical specifications involved.

It highlights the precision and detail required in garment creation.

| Feature | Tech Pack | Technical Pack |

| Definition | Comprehensive guide | Emphasis on specifications |

| Purpose | Production instructions | Technical details and standards |

| Common Use | Industry-wide | Mainly in formal contexts |

Both documents assist designers in communicating with factories.

They ensure that the final product meets the original design intent.

While they hold the same information, using “technical pack” might indicate a focus on specifications or standards, whereas “tech pack” is often more casual.

This distinction typically depends on context rather than differing content.