Creating a shirt tech pack is essential for anyone in the garment industry.

It serves as a comprehensive guide that ensures all stakeholders are aligned on the design, materials, construction details, and production processes.

This structured approach minimizes costly errors and miscommunications, ultimately saving you time and money.

Without a well-prepared tech pack, you risk potential pitfalls that could derail your production timeline.

From the designer to the manufacturer, every step relies on clear communication and a techpack acts as a crucial reference point.

By providing detailed specifications, you empower your team to create garments that meet your expectations.

Understanding the importance of a shirt tech pack not only enhances your workflow but also elevates the quality of your products.

A tech pack is more than just a document; it is a vital tool for successful collaboration, ensuring that your vision is accurately translated into the final product.

Essentials of a Shirt Tech Pack

A well-structured shirt tech pack is crucial for translating your design vision into a finished product.

It ensures that every detail is communicated effectively to manufacturers, covering key aspects like sketches, materials, and construction techniques.

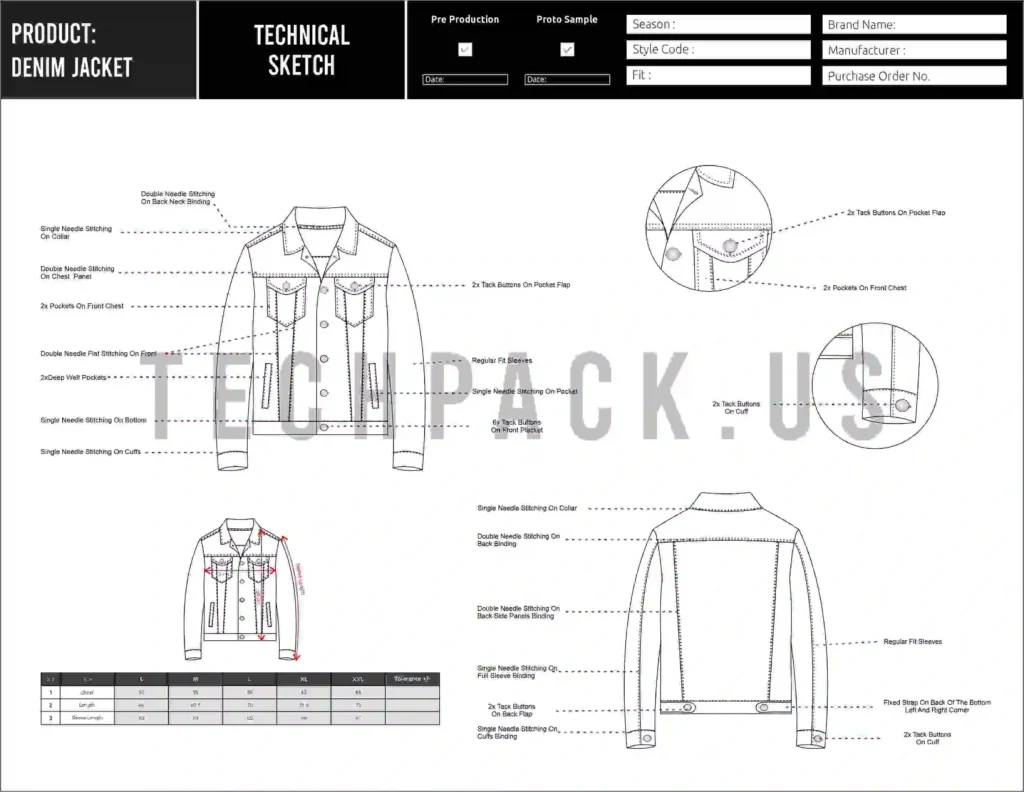

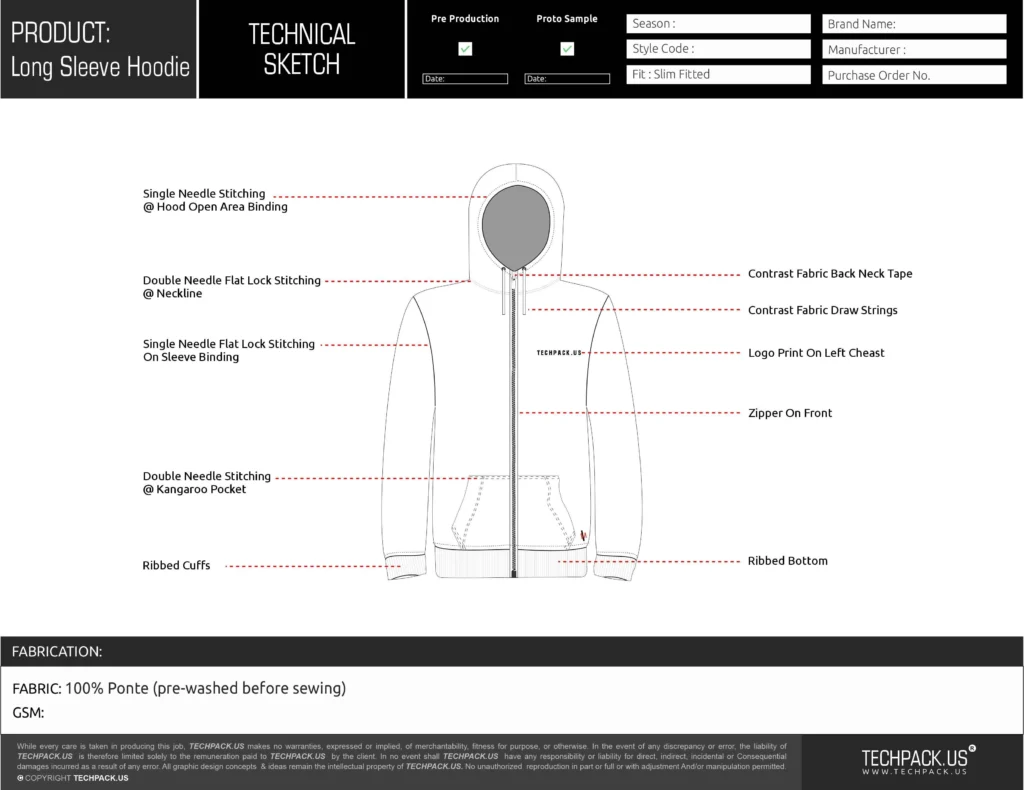

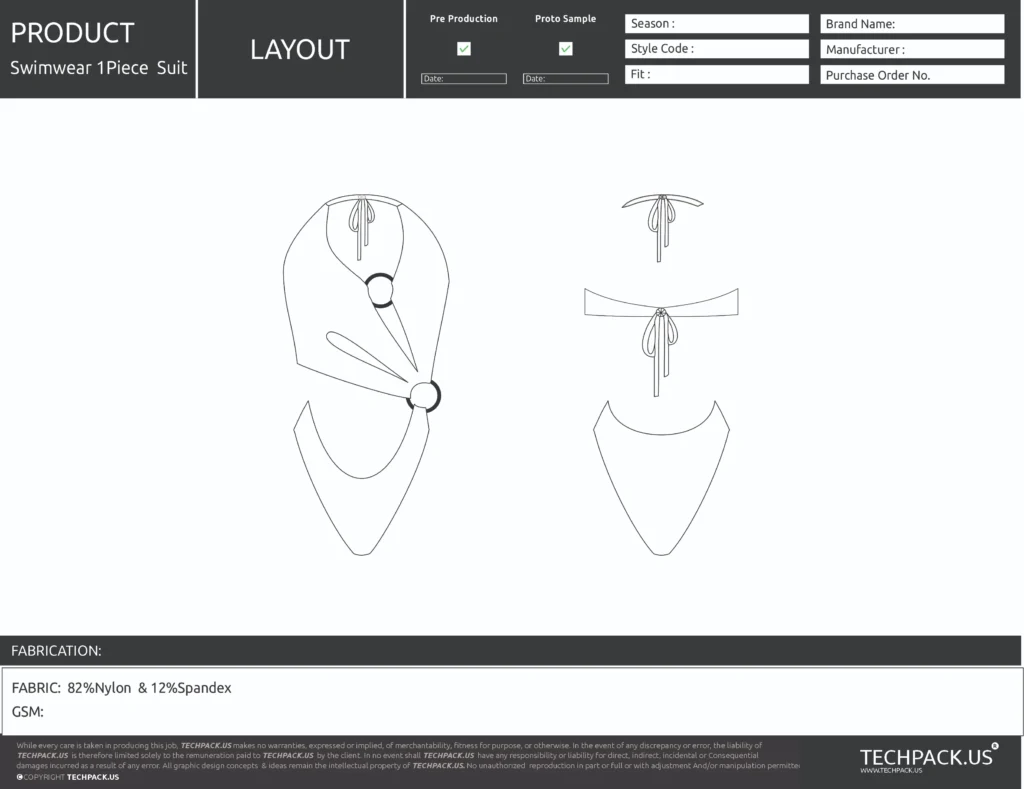

Technical Sketches for shirt tech pack

Technical sketches serve as the visual foundation of your shirt design.

They should clearly illustrate the front, back, and side views, highlighting important features like seams, hems, and any unique design elements.

Make sure your sketches are detailed but not overly complicated.

Key elements to include Shirt tech pack:

- Flat sketches that outline the design perspective.

- Labeling of design features like pockets, collars, and buttons.

- Color references that indicate specific hues and patterns.

A well-executed technical sketch minimizes the chances of miscommunication during production.

Materials and Components

Selecting the right materials and components is vital for the quality and functionality of your shirt.

Your Shirt tech pack should specify the type of fabric, including information on weight, texture, and durability.

Consider including:

- Fabric specifications, such as cotton, polyester, or blends.

- Color codes that match your design vision.

- Trims and accessories, including buttons, zippers, and labels.

Detailing these components helps ensure that the manufacturer understands the desired aesthetic and performance qualities of the shirt.

Construction Details

Construction details should outline how your shirt will be assembled.

This includes stitching types, seam finishes, and any special techniques required for a polished look.

Areas to include:

- Stitch type: Specify whether you want single-needle or double-stitched seams.

- Seam allowances: Indicate the width that should be allocated for seams.

- Finishing techniques, such as folding or bias tape usage.

Providing precise construction guidelines helps avoid mistakes and ensures your shirt meets your quality standards.

Role in the Manufacturing Process

A shirt tech pack serves several critical functions in the manufacturing process.

It ensures precision, enhances communication among stakeholders, and streamlines production workflows, ultimately leading to higher-quality products and reduced errors.

Ensuring Accuracy

A shirt tech pack outlines each detail of the shirt’s design.

This includes technical drawings, fabric specifications, and measurements.

When you provide clear guidelines, manufacturers can produce garments that closely match your vision.

Incorporating size charts and material descriptions helps to eliminate guesswork.

By specifying all elements, you minimize the risk of errors that could occur due to miscommunication.

This accuracy is vital in maintaining your brand’s quality standards and customer satisfaction.

Facilitating Communication

Communication is key in the manufacturing landscape.

Everyone has access to the same information, reducing discrepancies that can arise during production.

Important details, like construction methods and finishing touches, are documented.

This clarity enhances collaboration and can significantly reduce back-and-forth delays.

Effective communication supported by a shirt tech pack fosters a smooth workflow, allowing production to stay on track.

Streamlining Production

When manufacturers have a comprehensive reference, they can efficiently allocate resources and schedule production runs.

This organization reduces lead times and helps avoid costly rework.

Manufacturing teams can easily identify and address issues early in the process, promoting a more fluid production cycle.

As a result, you achieve better alignment between design intentions and final products.

Advantages for Designers and Manufacturers

Utilizing a tech pack provides significant benefits for both designers and manufacturers.

The clarity and detail included in a tech pack directly contribute to smoother processes and improved outcomes.

Reducing Errors and Revisions

By clearly outlining design specifications, material choices, and size charts, inconsistencies become less likely.

This reduces the number of revisions needed once manufacturing begins.

Fewer revisions lead to a more efficient workflow and shortened lead times.

When every detail is documented, manufacturers can produce garments that meet your exact expectations, reducing misunderstandings and costly mistakes.

Improving Cost-Efficiency

Shirt Tech packs are instrumental in enhancing cost-efficiency throughout the manufacturing process.

When designs are precise and well-documented, manufacturers can estimate production costs more accurately.

Clear specifications help prevent unexpected expenses arising from miscommunications or changes during production.

Eliminating guesswork allows you to allocate budgets effectively, ensuring that resources are used wisely.

Enhancing Product Consistency

Consistency in product quality is critical for brand reputation.

By providing detailed technical specifications and quality standards, you empower manufacturers to replicate your designs accurately.

This consistency helps maintain a strong brand identity and customer loyalty, as customers come to expect quality in every purchase.

Aligned expectations between you and the manufacturer can prevent discrepancies, leading to higher customer satisfaction rates and fewer returns.

Tools Used to Create a Tech Pack

Creating a professional tech pack requires the right tools to ensure accuracy and efficiency. Designers and manufacturers rely on various software and platforms to streamline the process.

- Adobe Illustrator – Used for creating detailed technical sketches and design layouts.

- CLO 3D/Marvelous Designer – Helps in developing 3D prototypes to visualize garment construction.

- Techpacker – A dedicated platform for creating tech packs with an intuitive interface and collaboration features.

- Excel/Google Sheets – Used for organizing measurement charts, material specifications, and costing details.

- CorelDRAW – An alternative to Adobe Illustrator for vector-based technical drawings.

- PLM (Product Lifecycle Management) Software – Helps manage the entire production process from design to final manufacturing.

Using these tools ensures that your tech pack is professional, clear, and easy to follow, leading to better communication and efficient production.