Pattern cutting is one of the most basic foundations of the fashion and apparel industry. It is the process of transforming a clothing design into exact paper or digital patterns that can be utilized to cut fabric and deliver garments. Without legitimate design cutting, even the most creative designs fall flat in fitting accurately or meet fabrication benchmarks. In modern dress manufacturing, design cutting bridges the gap between design concepts and mass production, ensuring consistency, precision, and quality.

At techpack.us, pattern cutting is treated as a basic stage within a professional clothing techpack, as it directly influences fit, fabric usage, garment cost, and generation efficiency. Whether you are making an essential t-shirt or a detailed hoodie tech pack, accurate pattern cutting is non-negotiable.

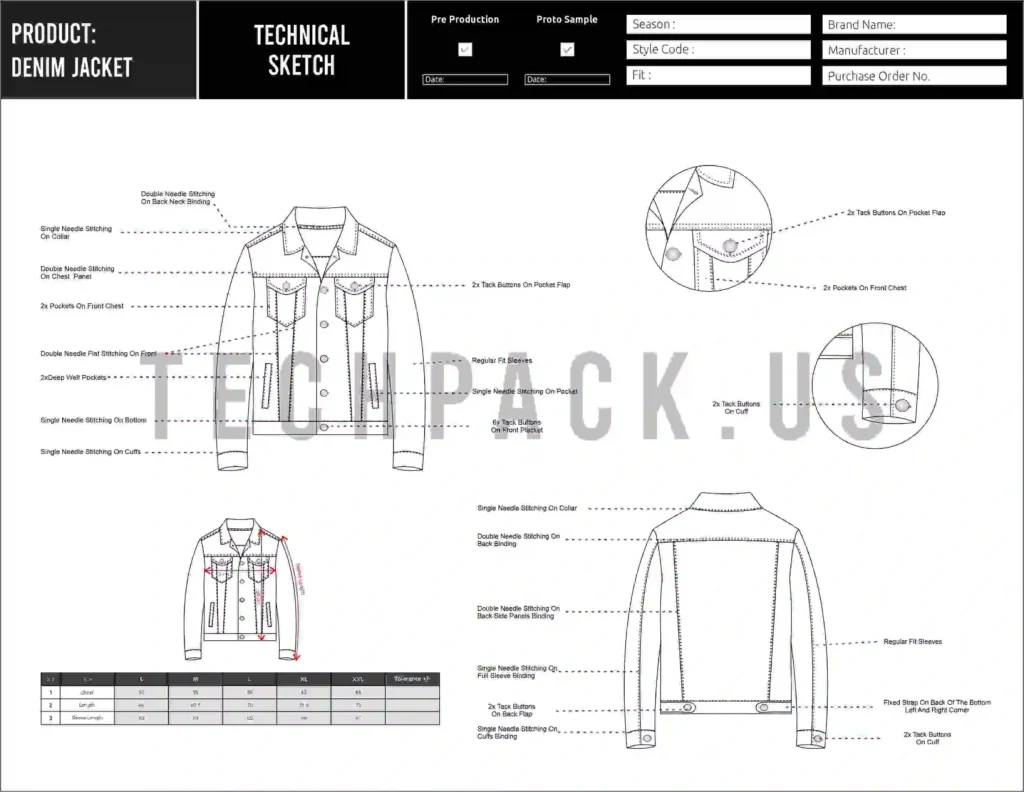

Pattern cutting includes interpreting design portrayals, measurements, and measuring charts to create exact templates for each garment component. These formats are then used by manufacturers to cut fabric pieces reliably for all sizes. In today’s apparel industry, design cutting is regularly done carefully using a CAD program, making it simpler to coordinate with a tech pack case and communicate consistently with factories.

Why Is Important in Clothes Manufacturing

In clothes manufacturing, design cutting guarantees that each garment delivered matches the intended plan and fit. A well-cut pattern reduces fabric wastage, minimizes testing mistakes, and speeds up generation timelines. Poor pattern cutting, on the other hand, leads to fitting issues, rejected tests, and expanded fabricating costs.

Pattern cutting plays a crucial part in scaling generation. When a pattern is accurately created, it can be evaluated into different sizes while keeping up proportional adjustment. This is especially imperative for high-demand things like t-shirts, sweatshirts, and hoodies. A single mistake in pattern cutting can duplicate over hundreds or thousands of units, making exactness vital from the start.

For brands working with overseas factories, pattern cutting included in a detailed clothing techpack helps avoid errors. Clear designs guarantee that manufacturers interpret plans accurately, indeed, without constant back-and-forth communication.

Types of Pattern Cutting Methods

There are a few pattern-cutting methods utilized in the fashion industry, depending on garment complexity and production needs. Level design cutting is the most common strategy, where patterns are created from basic blocks using measurements. This procedure is broadly used for t-shirts, shirts, and casual wear and is frequently included in a t-shirt techpack.

Draping is another strategy where fabric is formed directly on a dress frame to make patterns. This strategy is commonly utilized for high-fashion or complex garments, but is afterward converted into level designs for production. Present-day attire brands frequently combine hanging with advanced design cutting for efficiency.

Digital pattern cutting has become the industry standard in professional clothes manufacturing. CAD-based designs integrate easily into a tech pack example, permitting manufacturers to visualize, measure, and alter designs before generation starts. This approach diminishes blunders and improves generation accuracy.

Pattern Cutting and the Clothing Techpack

A clothing techpack is a total generation document that communicates each detail of a garment to producers, and pattern cutting is a central component of it. Patterns define garment structure, crease placement, fit, and construction details. Without designs, a tech pack remains fragmented and unsafe for manufacturing.

At techpack.us, pattern cutting is adjusted with measurement charts, construction notes, and texture details within the tech pack. This ensures that manufacturers receive a clear, proficient reference that eliminates mystery. Whether it is a t-shirt techpack or a sweatshirt tech pack, exact designs help factories achieve reliable results over bulk production.

Including design cutting details in a tech pack also speeds up sampling. Manufacturers can move straightforwardly to test development without requiring extra clarification, saving both time and cost.

Pattern Cutting for T-Shirts

Pattern cutting for t-shirts centers on simplicity, fit, and consistency. A well-developed t-shirt design ensures adjusted extents over all sizes, while maintaining comfort and style. T-shirt pattern cutting includes body boards, sleeves, necklines, and seam allowances, all of which are reported in a t-shirt techpack.

In mass clothes manufacturing, t-shirt patterns must be optimized for fabric efficiency to reduce waste. Small changes in design format can significantly impact production costs at scale. This is why professional pattern cutting is fundamental, indeed, for basic garments.

When included in a tech pack case, t-shirt patterns help manufacturers keep up with brand guidelines and replicate designs accurately over multiple production runs.

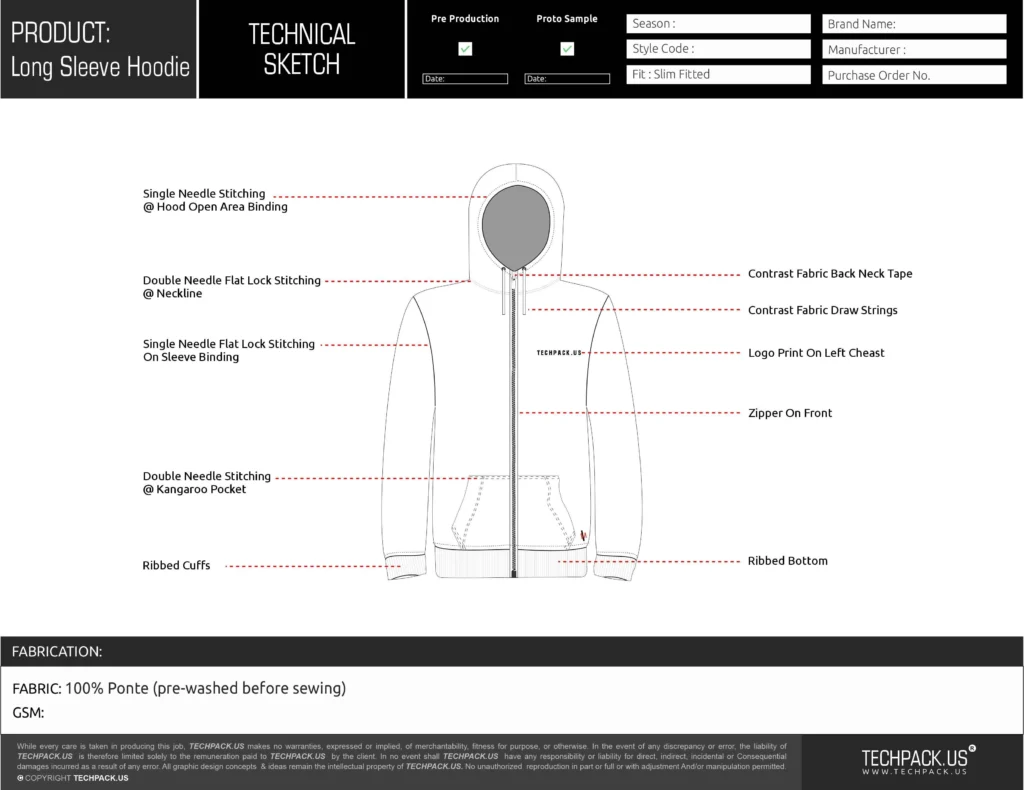

Pattern Cutting for Hoodies and Sweatshirts

Pattern cutting becomes more complex when managing layered garments such as hoodies and sweatshirts. A hoodie tech pack incorporates multiple design pieces, such as the hood, sleeves, cuffs, belt, and kangaroo pockets. Each piece must adjust perfectly to guarantee comfort, durability, and tasteful appeal.

Similarly, a sweatshirt tech pack requires exact pattern cutting to accommodate rib trims, loose fits, and fabric extension. Incorrect patterns can result in tight armholes, uneven hems, or poor drape, all of which influence client satisfaction.

At techpack.us, hoodie and sweatshirt pattern cutting is created with real-world production considerations in mind, ensuring patterns are factory-ready and optimized for bulk manufacturing.

Pattern Grading and Size Scaling

Pattern grading is the process of increasing or decreasing pattern sizes while maintaining correct extents. This is a crucial step in dress manufacturing, particularly for brands offering multiple size ranges. Pattern reviewing ensures that garments fit reliably over sizes without distortion.

Accurate evaluation is directly connected to original pattern quality. A poorly cut base design will lead to incorrect grading results. This is why proficient brands depend on master design cutting as part of their clothing techpack.

Pattern reviewing details are often included in a tech pack case, permitting manufacturers to follow size specifications precisely during production.

Digital Pattern Cutting and Modern Manufacturing

Digital pattern cutting has revolutionized the attire industry. Using CAD software, originators can make, alter, and test designs before any texture is cut. This approach decreases examination costs and improves production efficiency.

Digital patterns coordinated consistently into a clothing techpack, permitting factories to get to correct measurements and formats. For international manufacturing, digital design cutting ensures consistent results regardless of location.

At techpack.us, computerized design cutting bolsters modern clothes manufacturing workflows and helps brands move from concept to production with certainty.

Common Mistakes to Avoid

One of the most common mistakes in pattern cutting is overlooking texture behavior. Different fabrics extend, shrivel, and wrap differently, and patterns must account for this. Another common issue is wrong crease allowances, which can affect garment fit and durability.

Skipping proficient pattern cutting frequently leads to rehashed test revisions, increased costs, and postponed dispatches. Counting precise design cutting in a t-shirt techpack, hoodie tech pack, or sweatshirt tech pack helps avoid these costly mistakes.

Clear documentation inside a tech pack example guarantees manufacturers follow designs accurately and keep up quality measures.

How Techpack.us Supports Pattern Cutting

At techpack.us, pattern cutting is coordinated into a complete apparel production system. Each pattern is created to adjust to garment estimations, construction strategies, and manufacturing capabilities. This approach ensures that designs are not only fair but also correct and production-ready.

Whether you are creating t-shirts, hoodies, or sweatshirts, techpack.us gives professional pattern cutting that bolsters proficient dress manufacturing and minimizes production risks.

By combining design cutting with a detailed clothing techpack, brands pick up clarity, consistency, and control over their manufacturing process.

FAQs

What is pattern cutting in fashion?

Pattern cutting is the process of making formats used to cut fabric pieces for garment generation. It converts design thoughts into accurate, production-ready patterns.

Why is design cutting imperative in clothes manufacturing?

Pattern cutting guarantees proper fit, diminishes texture waste, and allows manufacturers to create garments reliably at scale.

Is design cutting included in a clothing techpack?

Yes, professional design cutting is a key component of a complete clothing techpack and makes a difference for producers get the garment construction clearly.

How does pattern cutting contrast for t-shirts and hoodies?

T-shirts use simpler patterns, whereas hoodies require different components such as hoods, sleeves, and pockets, making design cutting more complex.

Can digital pattern cutting move forward production quality?

Yes, digital pattern cutting increases accuracy, decreases errors, and coordinates easily with a tech pack example for modern manufacturing.

Does techpack.us give pattern-cutting services?

Yes, techpack.us offers professional pattern cutting as part of its comprehensive tech pack arrangements for effective clothes manufacturing.