In the fashion industry, quality is everything. A garment can have the loveliest design, the finest fabric, and the ideal fit, but if it doesn’t meet quality measures, it can rapidly lead to client dissatisfaction and brand damage. This is where garment quality assurance (QA) comes in.

At techpack.us, we accept that garment quality confirmation is not an afterthought—it’s a significant step in the generation process. From the most punctual plan stages, utilizing detailed tech packs, to the last inspections, recently garments hit the racks, QA ensures that design brands convey items that meet or surpass expectations.

This guide will explore what garment quality assurance is, its importance, the key forms involved, and how brands can implement effective QA practices to construct belief and accomplish long-term victory.

What Is Garment Quality Assurance?

Garment quality assurance (QA) is the precise process of ensuring that each piece of clothing meets established quality benchmarks. It covers each organization of the generation cycle—design, fabric sourcing, cutting, sewing, wrapping up, packaging, and distribution.

While quality control (QC) regularly refers to the review of wrapped-up items, quality confirmation is broader. QA is proactive, centering on avoiding botches before they happen.

In easier terms:

- QA = Prevention (making sure the preparation is correct)

- QC = Detection (catching mistakes after they occur).

By actualizing a solid quality affirmation system, brands can diminish abandonment, improve efficiency, and reinforce their notoriety in the competitive fashion industry.

Why Is Garment Quality Assurance Important?

- Customer Satisfaction

Customers anticipate a dress that fits well, feels comfortable, and lasts long. Poor-quality garments lead to disappointment, negative surveys, and high return rates.

- Brand Reputation

In fashion, notoriety is everything. One bunch of flawed garments can damage years of hard-earned belief. QA guarantees reliable quality, building long-term loyalty.

- Cost Reduction

Catching mistakes early avoids expensive rework, wasted materials, and shipping imperfect items. Strong QA frameworks save cash in the long run.

- Compliance With Standards

Brands must meet universal security and quality standards (ISO, ASTM, AATCC). Quality confirmation guarantees compliance, particularly for send-out markets

- Sustainability

Reducing defects implies decreasing waste. By improving quality from the beginning, brands minimize their natural footprint—a key concern in today’s feasible mold movement.

Key Elements of Garment Quality Assurance

-

Design Stage and Tech Packs

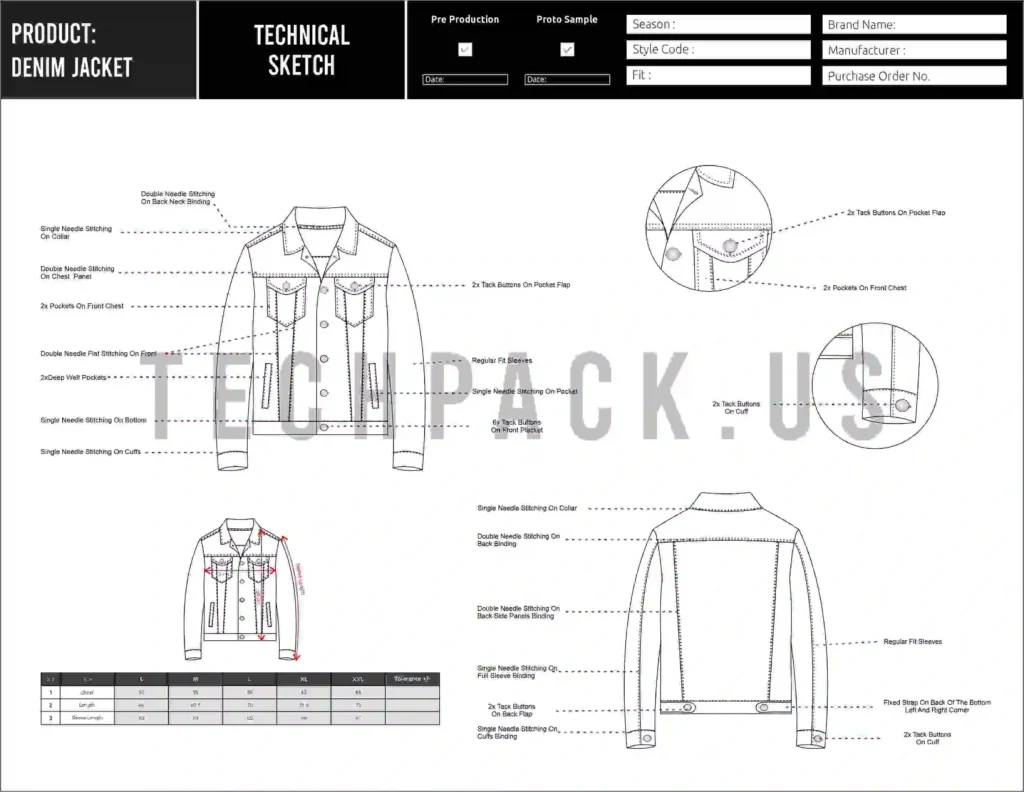

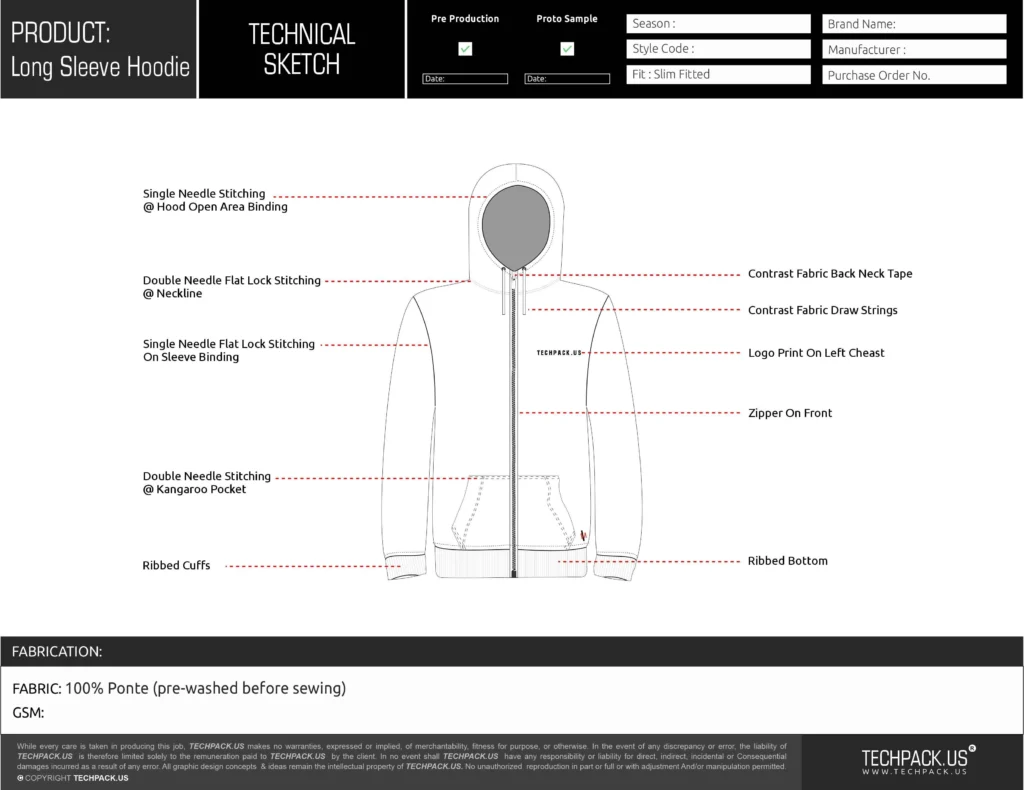

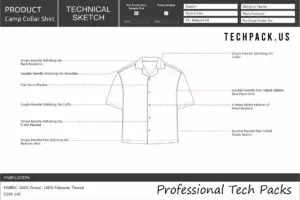

QA begins before a single garment is made. Detailed tech packs give producers the outline they need:

- Accurate measurements and measurement charts.

- Stitching and crease details.

- Fabric, trims, and extra specifications.

- Labeling, bundling, and branding requirements

At techpack.us, we make proficient clothing tech packs that eliminate mystery, guaranteeing your garment is made precisely as envisioned.

-

Fabric and Material Inspection

Fabric is the foundation of any garment. QA requires:

- Fabric Quality Tests (shrinkage, colorfastness, GSM).

- Trims and Accessories Check (zippers, buttons, labels).

- Defect Identification (ties, stains, holes).

Only affirmed fabrics move forward into production.

-

Cutting Stage Quality Assurance

Mistakes in cutting can destroy entire batches. QA at this organization includes:

- Checking markers and patterns against tech pack specifications.

- Ensuring the adjustment of fabric grain alignment.

- Inspecting cut pieces for precision before sewing.

-

In-Process Quality Checks

During sewing and assembly, QA inspectors monitor:

- Seam quality and fastening density.

- Alignment of panels and prints.

- Matching of patterns and stripes.

- Proper connection of labels and trims.

This decreases the chances of a revamp later

-

Finishing and Packaging QA

Garments are checked for:

- Loose strings, stains, or marks.

- Correct pressing and folding

- Accurate labeling and barcoding.

- Packaging compliance with brand benchmarks.

-

Final Inspection (AQL System)

The Acceptable Quality Limit (AQL) strategy is commonly utilized to decide if a clump of garments meets benchmarks. Inspectors arbitrarily select garments and test them against set criteria. If the abandons exceed the constraint, the batch is rejected.

Garment Testing in Quality Assurance

Testing is an imperative part of QA. Common tests include

- Fabric Tests: shrinkage, tearing quality, and abrasion resistance.

- Color Tests: colorfastness to wash, rub, sweat, and light.

- Performance Tests: crease quality, extend recuperation, pilling resistance.

- Safety Tests: combustibility, chemical substance (important for wear).

By joining these tests to QA, brands guarantee durability and compliance.

Challenges in Garment Quality Assurance

- Fast Fashion Pressure – Brief lead times frequently compromise quality.

- Supplier Inconsistency – Diverse factories may interpret instructions differently.

- Rising Costs – QA frameworks require speculation in talented staff and technology.

- Sustainability Requests – Eco-friendly forms must align with quality standards.

At techpack.us, our detailed tech packs help brands overcome these challenges by standardizing instructions and guaranteeing smooth communication with producers.

How Tech Packs Support Garment Quality Assurance

A well-prepared tech pack is one of the most powerful QA instruments in fashion fabricating. It ensures:

- Clarity – Every detail (measurements, trims, textures) is documented.

- Consistency – All production lines follow the same guidelines.

- Accountability – Producers are less likely to stray from specifications.

- Efficiency – Less back-and-forth between brand and factory.

Whether you’re making a t-shirt tech pack, sweatshirt tech pack, or hoodies tech pack, tech packs decrease mistakes and ensure higher quality garments

Implementing Quality Assurance in Garment Manufacturing

Here’s how brands can build a successful QA system:

- Create Professional Tech Packs – The first step to quality confirmation is clear instructions.

- Set Quality Benchmarks – Characterize worthy imperfection levels, texture measures, and sewing requirements.

- Train Staff – Guarantee everybody, from architects to line laborers, gets the QA protocols.

- Regular Reviews – Review materials, in-process pieces of clothing, and wrapped up goods.

- Use Innovation – Embrace 3D plan, advanced tech packs, and robotized QA tools.

- Feedback Circle – Collect customer feedback and feed it into future QA improvements.

Final Thoughts

Garment quality confirmation is not fair, approximately catching mistakes—it’s about avoiding them. From concept to customer, QA safeguards your brand’s notoriety, decreases costs, and builds long-term belief with consumers.

At techpack.us, we get it that quality begins with exactness. Our tech pack gives the detailed instructions producers require to create garments that coordinate with your vision while adhering to the most noteworthy quality standards. Whether it’s a clothing tech pack, t-shirt tech pack, sweatshirt tech pack, or hoodies tech pack, our mission is to ensure your items are production-ready and built to last.

By contributing to garment quality affirmation nowadays, your brand can convey a design that not only looks incredible but also stands the test of time.

FAQs About Garment Quality Assurance

- What is the difference between quality confirmation and quality control in garments?

Quality assurance is proactive, focusing on preventing defects, whereas quality control is reactive, inspecting for defects in completed garments.

- How do tech packs help in garment quality assurance?

Tech pack give clear, detailed, enlightening information on estimations, textures, trims, and stitching, ensuring producers follow brand specifications without guesswork.

- What tests are important in garment quality assurance?

Fabric shrinkage, colorfastness, crease quality, pilling resistance, and security tests (for kidswear) are essential.

- Why is garment QA important for small fashion brands?

Small brands depend intensely on customer belief. A single poor-quality bunch can harm their reputation. QA helps them keep up consistency and professionalism.

- What is AQL in garment quality assurance?

AQL (Acceptable Quality Limit) is a standard assessment strategy where an irregular test of garments is checked against defined defect limits.