In the world of dress manufacturing, accuracy and communication define victory. Whether you’re making a lively streetwear hoodie or an extravagant athleisure piece, a Raglan Hoodie CAD Tech Pack guarantees your design is precisely interpreted from concept to the last product.

At techpack.us, we help originators, apparel startups, and fashion brands set up production-ready Tech Packs that streamline each arrange of manufacturing. From specialized sketches to fabric details and measurement specs, our CAD-based tech packs help you collaborate easily with clothing producers in the USA and worldwide.

This guide walks you through everything you require to know about Raglan Hoodie Tech Packs, how they’re built, why they matter, and what a professional Tech Pack example looks like.

What Is a Raglan Hoodie CAD Tech Pack?

A Raglan Hoodie CAD Tech Pack is a comprehensive computerized outline that details each viewpoint of your hoodie design—from sewing lines to texture composition. “CAD” (Computer-Aided Design) alludes to utilizing specialized design software like Adobe Illustrator, CorelDRAW, or CLO3D to create precise computerized drawings of your garment.

Unlike hand portrays, CAD drawings deliver producers an exact visual enlightenment. A well-designed Tech Pack includes:

- Front and back CAD views of the raglan hoodie

- Detailed sewing lines, crease placements, and texture panels

- Rib sleeve and trim specifications

- Drawstring and hood construction details

- Fabric weight, composition, and color codes

- Size estimations and evaluating rules

- Label and bundling instructions

In basic terms, your Tech Pack is your hoodie’s “instruction manual” for generation — the record your clothing producer will depend on to bring your vision to life.

Why the Raglan Hoodie Needs a CAD Tech Pack

The raglan hoodie has a distinct plan — its diagonal sleeve crease runs from the collar to the underarm, advertising greater portability and an energetic aesthetic. Since of these unique construction lines, your Tech Pack must precisely characterize sleeve points, fabric grain direction, and design connections.

Without a detailed CAD tech pack, miscommunication is inevitable. Producers might confuse the sleeve bend or hood dimensions, leading to expensive inspection errors.

Here’s why a CAD-based Tech Pack is essential:

- Accuracy in Design – CAD guarantees steady extents, symmetry, and crease placements.

- Reduced Sampling Errors – With correct measurements and visuals, producers can deliver exact samples to begin with.

- Streamlined Production – All details — from texture weight to trims — are standardized, making a difference that factories arrange materials and time efficiently.

- Professional Presentation – A proficient Tech Pack case awes production lines and sourcing accomplices, signaling that your brand gets its production necessities.

The Components of a Raglan Hoodie CAD Tech Pack

At techpack.us, we structure each hoodie Tech Pack with clear, easy-to-read areas. Here’s what a total Raglan Hoodie CAD Tech Pack regularly includes:

- Cover Page

Includes the project title (e.g., Men’s Raglan Hoodie – Fall 2025 Collection), brand name, designer name, date, and form number. This helps keep all parties adjusted as upgrades are made.

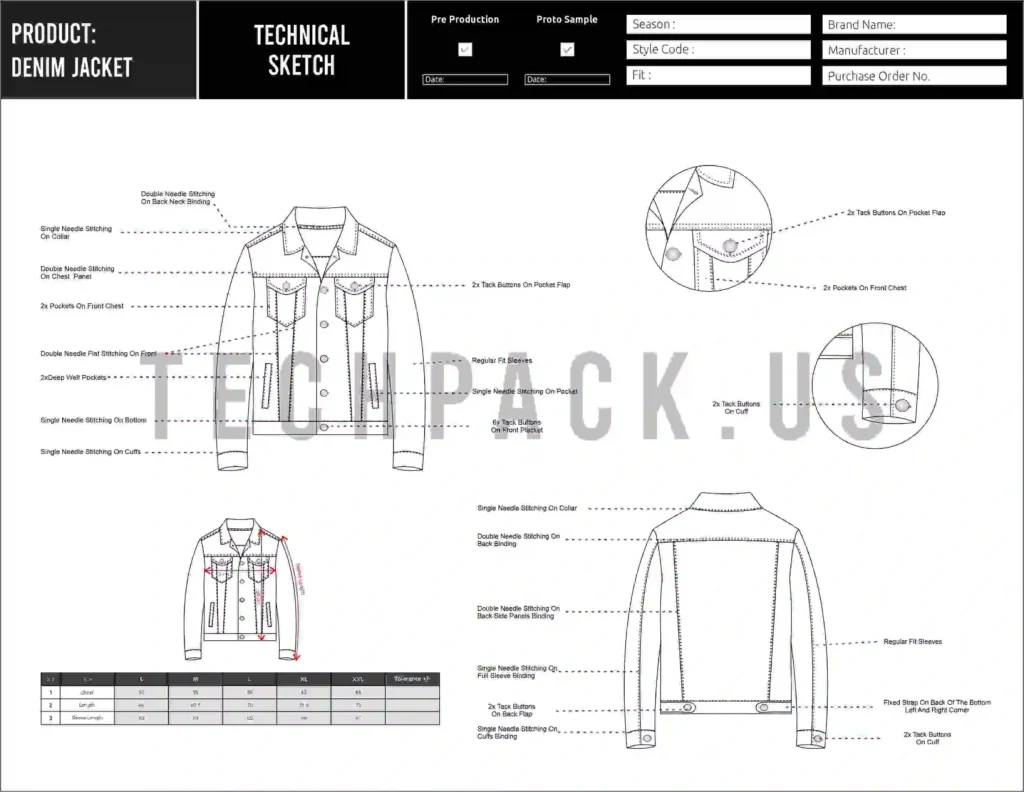

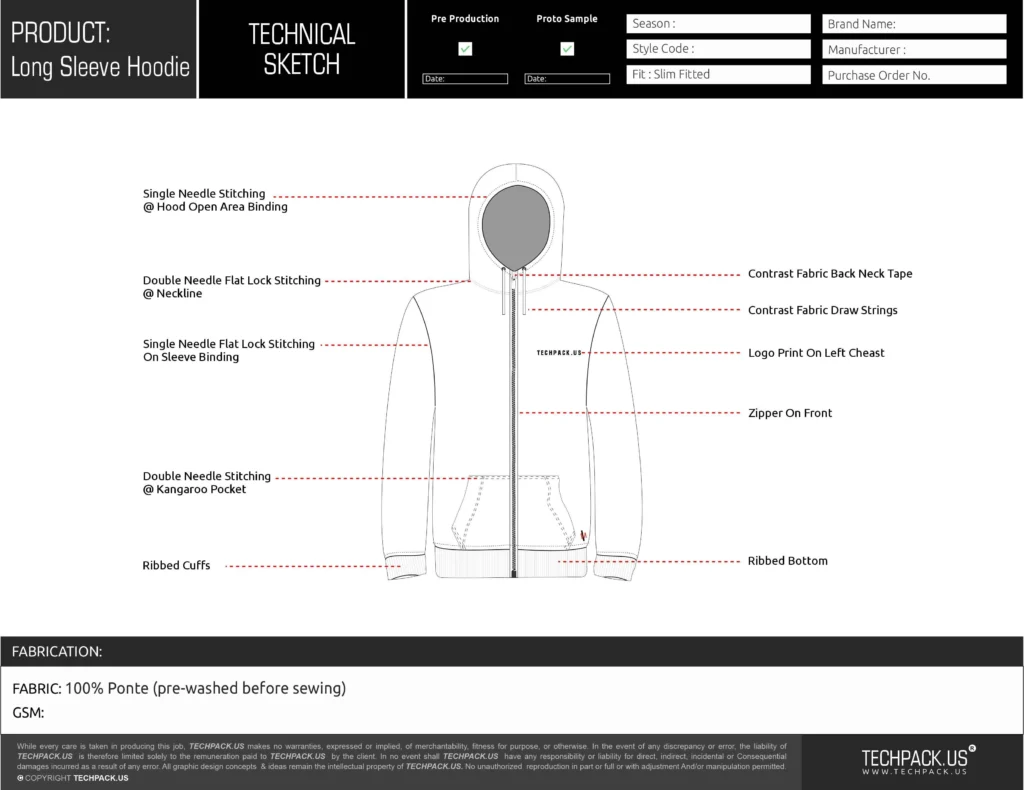

- Technical Drawings (CAD Flats)

These are front, back, and side sees made utilizing CAD software. Each drawing highlights crease lines, fastening details, hood shape, kangaroo take design, and rib placements.

A Tech Pack example might incorporate callouts like:

- “Double-needle topstitch along raglan seams”

- “3-panel hood with level drawcord channel”

- “1×1 rib at sleeve and hem”

- Bill of Materials (BOM)

A table posting all the components utilized in your hoodie:

- Main texture: 80% cotton / 20% polyester downy, 320 GSM

- Rib texture: 95% cotton / 5% elastane

- Drawcord: Level cotton rope, 10mm width

- Eyelets: Metal, matte dark finish

- Label: Woven brand name, center back neck

This area is crucial for clothing producers in the USA when sourcing materials or assessing dress fabricating costs.

- Colorways and Artwork

Show each hoodie color variety and any symbol situations, print techniques (screen print, embroidery, heat transfer), and Pantone codes. CAD allows exact visualization of the artwork situation.

- Measurement Specs

A graded size chart detailing every dimension — from chest width to sleeve length. Example:

| Measurement | XS | S | M | L | XL |

| Chest (1” below armhole) | 20” | 21” | 22” | 23” | 24” |

| Body Length (HPS) | 27” | 28” | 29” | 30” | 31” |

| Sleeve Length (from center back) | 33” | 34” | 35” | 36” | 37” |

- Construction Details

Clarifies fastening sorts, crease allowances, and finishing methods.

Example callouts:

- Overlock fasten on inner seams

- Twin-needle topstitch on raglan line

- Bar tack support at take corners

- Labeling & Packaging Instructions

Include placement graphs for neck labels, hangtags, and bundling rules such as “Folded level with hood tucked in polybag.”

- Revision History

A log to track updates — pivotal for communication between the plan team and producers.

How Techpack.us Helps Build Raglan Hoodie Tech Packs

At techpack.us, we specialize in changing your thoughts into factory-ready documentation. Our team of fashion originators, pattern makers, and CAD experts guarantees your Tech Pack is clear, detailed, and production-focused.

We don’t fair make visuals — we direct you through the full-dress manufacturing process:

- Concept Sketch to CAD Conversion – Turning your portraits into digital, specialized drawings.

- Material & Trim Guidance – Helping you select suitable fabrics, ribbing, and accessories.

- Professional Layout – Organized tech pack formats with all basic sections.

- Manufacturer Coordination – We adjust your tech pack with your favored clothing producers in the USA or abroad.

When you work with us, your tech pack is outlined to minimize testing rounds, decrease costs, and speed up time-to-market.

Why a Good Tech Pack Saves Time and Money

A well-structured Tech Pack is more than a plan record — it’s a financial defense. Each unclear measurement or lost spec includes time and cost during sampling.

Here’s how a professional Raglan Hoodie Tech Pack benefits your brand:

- Fewer Revisions: Production lines can deliver exact tests in fewer attempts.

- Cost Efficiency: Clear details mean less fabric wastage.

- Scalability: Once a tech pack is prepared, you can effectively duplicate or adjust it for future collections.

- Consistent Quality: Whether creating 50 or 5,000 units, each hoodie will coordinate with your plan standards.

At techpack.us, we get it that effective clothes manufacturing starts with clarity — and your Tech Pack gives precisely that.

Tech Pack Example: Raglan Hoodie Breakdown

Here’s a streamlined Tech Pack example for a Men’s Raglan Hoodie:

Front View:

- Kangaroo stash with twofold topstitching

- Rib sleeve and hem

- 3-panel hood with cotton drawcord

- Flatlock fastening along raglan seams

Back View:

- Plain back

- Neck crease taped for comfort

Fabric:

- Brushed downy, 320 GSM

- Pre-shrunk, enzyme-washed

Trims:

- 10mm level cotton drawcord

- Branded woven neck label

Fit:

- Regular fit, unisex sizing

This is a streamlined version, but a proficient tech pack would incorporate reviewed measurements, fabric swatches, and detailed callouts for each plan.

Working With Clothing Manufacturers in the USA

Collaborating with clothing manufacturers in the USA offers major advantages for originators looking for quality and control. With a CAD Tech Pack, your communication with domestic industrial facilities becomes seamless.

Benefits include:

- Faster Turnaround: Shorter shipping and inspecting times.

- Better Quality Assurance: S. producers keep up tall measures of precision and durability.

- Ethical Practices: Compliance with reasonable labor laws and sustainability standards.

- Direct Collaboration: Simpler communication and location visits amid production.

By combining a precise Tech Pack with a solid nearby generation partner, you can raise your hoodie line to global standards.

Conclusion

The Raglan Hoodie CAD Tech Pack is the spine of effective dress manufacturing. It bridges the gap between your imaginative vision and the production floor — guaranteeing your garments are made precisely, reliably, and on time.

At techpack.us, we help brands construct industry-standard Tech Packs that rearrange communication with clothing manufacturers in the USA and worldwide. Whether you need a Tech Pack example, plan direction, or total attire generation bolster, our team guarantees your thoughts become market-ready products

Start your next hoodie project with certainty — sponsored by accuracy, professionalism, and the control of a well-built Tech Pack.

FAQs About Raglan Hoodie CAD Tech Pack

- What software is utilized to make a Raglan Hoodie CAD Tech Pack?

Most designers utilize Adobe Illustrator, CorelDRAW, or CLO3D for making detailed CAD drawings.

- How detailed should a Tech Pack be?

The more detailed, the superior. Each element—stitching, textures, trims, and labels—should be clearly specified.

- Do I need a Tech Pack for small-batch production?

Yes. Indeed, little orders advantage from Tech Packs since they avoid errors and expensive revisions.

- Can Techpack.us work with clothing manufacturers in the USA?

Absolutely. We collaborate with clothing manufacturers in the USA and globally to guarantee your generation runs smoothly.

- What is the average turnaround time for creating a Tech Pack?

Depending on design complexity, most Tech Packs are completed within 3–5 business days at techpack.us.