Introduction to Zipped vs Pull-Over Hoodies, Tech Pack, and Pattern

When developing hooded garments for advanced apparel brands, one of the most critical structural decisions is choosing between zipped and pull-over hoodies. Whereas both styles may show up comparable at first glance, their construction, pattern development, and generation workflow differ significantly. Understanding the technical differences between Zipped vs. Pull-Over Hoodies, Tech Pack, and Design requirements is fundamental for achieving accurate fit, productive Clothing Manufacturing, and consistent bulk generation results. At techpack.us, hoodie development is taken care of with exactness, integrating design engineering and detailed documentation inside a proficient clothing techpack to eliminate factory disarray and decrease sampling errors.

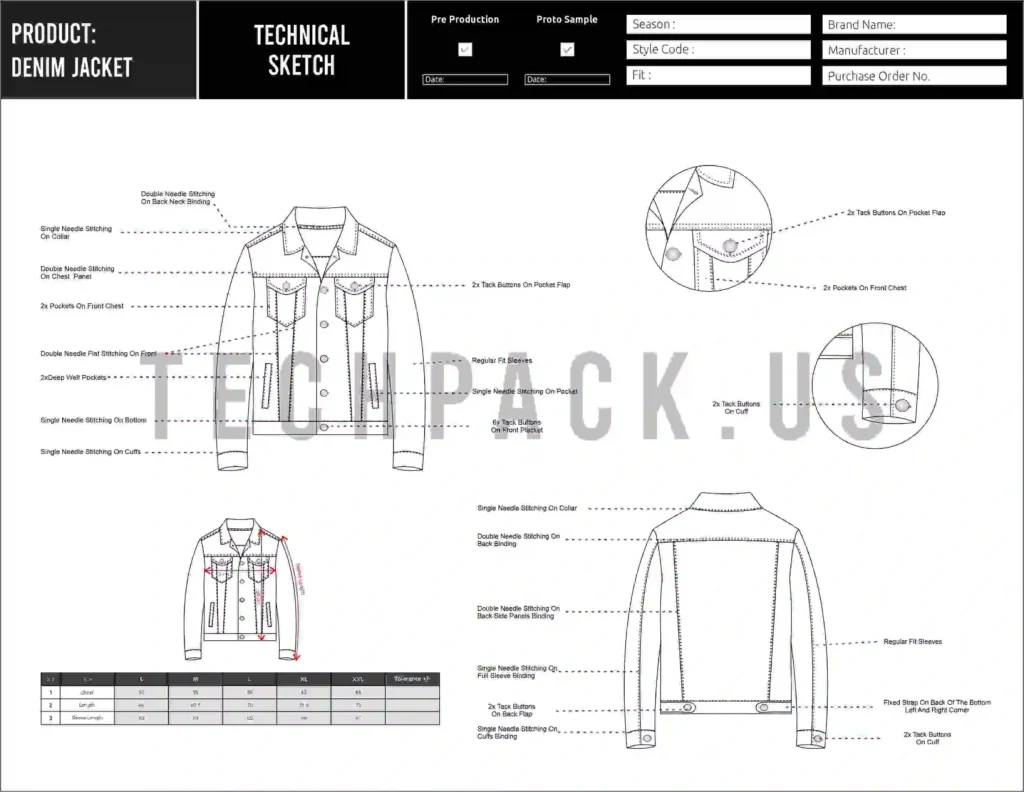

Structural Differences Between Zipped and Pull-Over Hoodies

Zipped hoodies highlight a full front opening secured with a zipper, making them more complex in construction. Pull-over hoodies have a seamless front board with no opening, offering basic simplicity but requiring an exact balance between the neckline and hood. These basic contrasts directly affect pattern cutting, evaluating, crease allowances, and technical documentation. Without a complete Hoodie Tech Pack and correctly engineered pattern pieces, factories may confuse plan intent, resulting in uneven hems, mutilated plackets, or ineffectively aligned hoods.

Pattern Development for Zipped Hoodies

From a Clothes Manufacturing viewpoint, zipped hoodies require additional components such as zipper tapes, zipper guards, topstitching details, and fortified plackets. Pattern development starts by dividing the front body board into two symmetrical parts. Each half includes seam allowance for the zipper connection, and the placket range must be stabilized to avoid extending. A well-developed Hoodie Tech Pack clearly characterizes zipper type, gauge, length, and installation method.

Without exact documentation in a clothing techpack, producers may substitute materials or misalign zipper placement, driving to generation flaws. A point-by-point tech pack example disposes of such dangers and guarantees arrangement exactness during sampling and bulk generation.

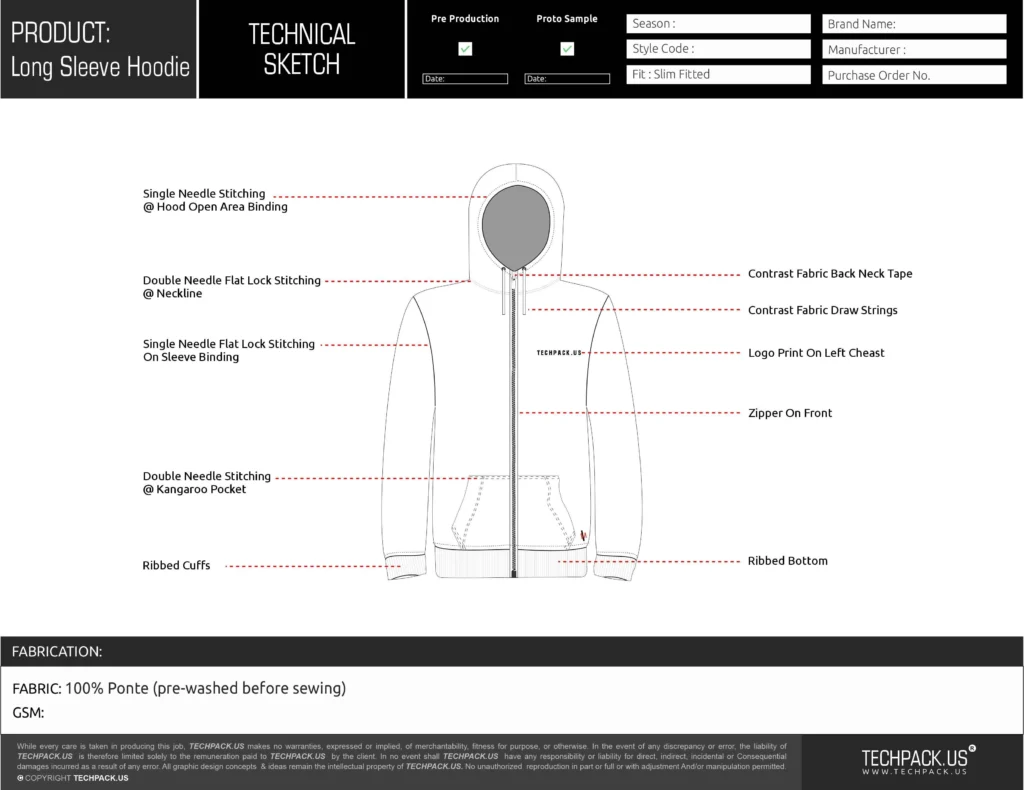

Pattern Development for Pull-Over Hoodies

Pull-over hoodies rely on a ceaseless front board, eliminating zipper integration but requiring exact neckline forming. The hood opening must adjust perfectly with the neckline bend to ensure comfort and auxiliary stability. Ribbed cuffs and waistbands must be relatively calculated to maintain extended recuperation and fit consistency.

Within a Sweatshirt Tech Pack or Hoodie Tech Pack, these specifications are archived alongside stitch sorts, crease construction strategies, and measurement tolerances. Proper design cutting guarantees pull-over hoodies keep up their silhouette over distinctive fabric weights and generation batches.

Fabric Considerations and Pattern Adjustments

Fabric behavior plays a vital part in hoodie design engineering. In Clothes Manufacturing, downy, French terry, and heavyweight cotton mixes react differently to pressure and washing. Zipped hoodies require fortification along zipper creases to prevent rippling. Pull-over hoodies require accurate shoulder incline calculations and hood depth balancing.

All these fabric-related alterations must be recorded within the clothing techpack to avoid production inconsistencies. Indeed, small miscounts in the extent rate can affect the last garment fit.

Cost and Production Complexity

Zipped hoodies typically include higher manufacturing costs due to the included hardware and labor time. Zipper installation increases gathering stages and quality inspection checkpoints. Pull-over hoodies, although easier in structure, still require exactness grading and hood alignment to avoid fitting issues.

Including grading rules and component details in a Hoodie Tech Pack ensures fetched efficiency and anticipates expensive revisions during bulk production. A structured tech pack case permits manufacturers to gauge generation costs precisely before inspection starts.

Grading and Size Scaling in Hoodie Production

Pattern grading determines how a base size scales over multiple size ranges. For zipped hoodies, zipper length must compare precisely to evaluated garment lengths. A grading error may cause zipper buckling or fabric pressure imbalance. Pull-over hoodies require corresponding scaling of hood profundity and neckline width to keep up stylish consistency.

Professional clothes manufacturing depends on exact grading formulas embedded in the clothing techpack to keep up consistency over production runs.

Comparing Hoodie Documentation to a T-Shirt Techpack

A t-shirt techpack is generally easier because t-shirts involve fewer construction elements. Hoodies, however, require layered documentation counting hood construction, rib trim measurements, drawstring details, and stash alignment.

When evaluating Zipped vs Pull-Over Hoodies, Tech Pack and Design documentation must incorporate level portrayals, measurement spec sheets, charge of materials, construction notes, and branding placement guides. Without comprehensive documentation, manufacturing mistakes become significantly more likely.

Pocket Construction Differences

Zipped hoodies regularly include split kangaroo pockets divided by the zipper crease. This requires symmetrical pattern precision. Pull-over hoodies use a persistent kangaroo stash, which must align precisely with belt ribbing and body proportions.

Clear take arrangement instructions inside a Sweatshirt Tech Pack or Hoodie Tech Pack ensure exact gathering during production.

Digital Pattern Cutting and Modern Workflow

Digital CAD-based design cutting has streamlined hoodie development. Designers can recreate seam arrangement, test measurements, and confirm reviewing accuracy before physical sampling. These computerized records integrate specifically into a clothing techpack and improve communication with manufacturers.

By utilizing digital systems, brands decrease sampling cycles and quicken go-to-market timelines while maintaining pattern precision.

Quality Control Considerations

Zipped hoodies experience zipper solidness testing, crease reinforcement checks, and placket alignment reviews. Pull-over hoodies require neckline extend testing and hood symmetry evaluation.

Documenting these assessment checkpoints in a tech pack example ensures reliable quality standards throughout Clothes Manufacturing.

Branding, Placement, and Technical Details

Logo placement, drawstrings, metal eyelets, and weaving must be absolutely defined. Zipped hoodies require symbol situating that avoids zipper obstructions, whereas pull-over hoodies give uninterrupted space for large graphics.

A comprehensive clothing techpack specifies arrangement measurements to maintain brand consistency over bulk orders.

Production Efficiency and Fabric Utilization

Effective pattern layouts decrease fabric waste. Zipped hoodies may produce slightly higher squander due to the separated front boards. Pull-over hoodies regularly permit more optimized cutting layouts.

Strategic pattern engineering recorded in a Hoodie Tech Pack bolsters cost control and maintainable Clothes Manufacturing practices.

Conclusion: Choosing the Right Hoodie Structure

Zipped and pull-over hoodies vary not only in appearance but also in basic complexity, cost suggestions, and design building prerequisites. Understanding Zipped vs Pull-Over Hoodies, Tech Pack, and Pattern differences ensures precise development, smoother testing, and reliable bulk production.

At techpack.us, professional Hoodie Tech Pack, Sweatshirt Tech Pack, and clothing techpack services help brands transform imaginative designs into factory-ready generation reports. Whether adapting standards from a t-shirt techpack or building complex hooded garments, exactness in design development remains the foundation of effective Clothes Manufacturing.

FAQs: Zipped vs Pull-Over Hoodies

What is the main auxiliary difference between zipped and pull-over hoodies?

Zipped hoodies incorporate a front opening with zipper integration, whereas pull-over hoodies have a continuous front panel without hardware.

Why is a Hoodie Tech Pack essential for production?

A Hoodie Tech Pack gives detailed estimations, construction strategies, materials, and review instructions fundamental for accurate Clothes Manufacturing.

Are zipped hoodies harder to manufacture?

Yes, zipped hoodies include more components and assembly steps, expanding production complexity.

How does pattern reviewing affect hoodie fit?

Accurate reviewing ensures relative scaling over sizes and prevents structural distortion.

Can a tech pack example reduce production errors?

Yes, a detailed tech pack example progresses communication and minimizes examining revisions.

Does techpack.us make both Hoodie and Sweatshirt Tech Packs?

Yes, techpack.us gives comprehensive Hoodie Tech Pack, Sweatshirt Tech Pack, and clothing techpack solutions tailored for adaptable production.