Introduction of Tech Packs

A tech packs is a crucial document in fashion and product design.

It serves as a blueprint for manufacturers.

It is an array of archives created by designers to specify their scheme to the producer who will transform this information into a finished garment.

It is an essential document used in the fashion and manufacturing industries.

It contains detailed specifications and guidelines that outline every aspect of a product, from materials to measurements.

This record serves as a communication device between you and your producers, guaranteeing that your vision is precisely interpreted into the ultimate item.

Additional details often found in a tech packs are:

- Colorways: This shows the different colors available for the product.

- Labels and Tags: Information about branding and care labels is included.

- Construction Details: This describes how the product should be made.

A well-prepared tech packs helps prevent misunderstandings between designers and manufacturers. It streamlines the production process and reduces errors.

Using a tech-packs can save time and money. It ensures that everyone involved has the same vision for the final product.

Fashion professionals rely on tech packs to communicate their design ideas clearly. This tool is essential for successful collaboration between all parties involved.

Tech packs Fundamentals

Techpacks are essential tools in the fashion and product design industries. They provide clear guidelines and detailed information needed to create a product. This section examines what a techpack is and its key components.

Definition and Purpose

It is a comprehensive document used by designers and manufacturers.

It outlines all the details required to produce an item, like clothing or accessories.

This document serves as a blueprint, clearly communicating the designer’s vision.

The purpose of a techpack is to ensure accurate production and minimize errors.

It allows manufacturers to understand what is needed, reducing misunderstandings. With a techpack, timelines and costs can be estimated more effectively.

A well-structured tech-packs helps maintain quality and efficiency during the production process.

What Should Be Included in a Tech Packs?

Here are the key elements to include:

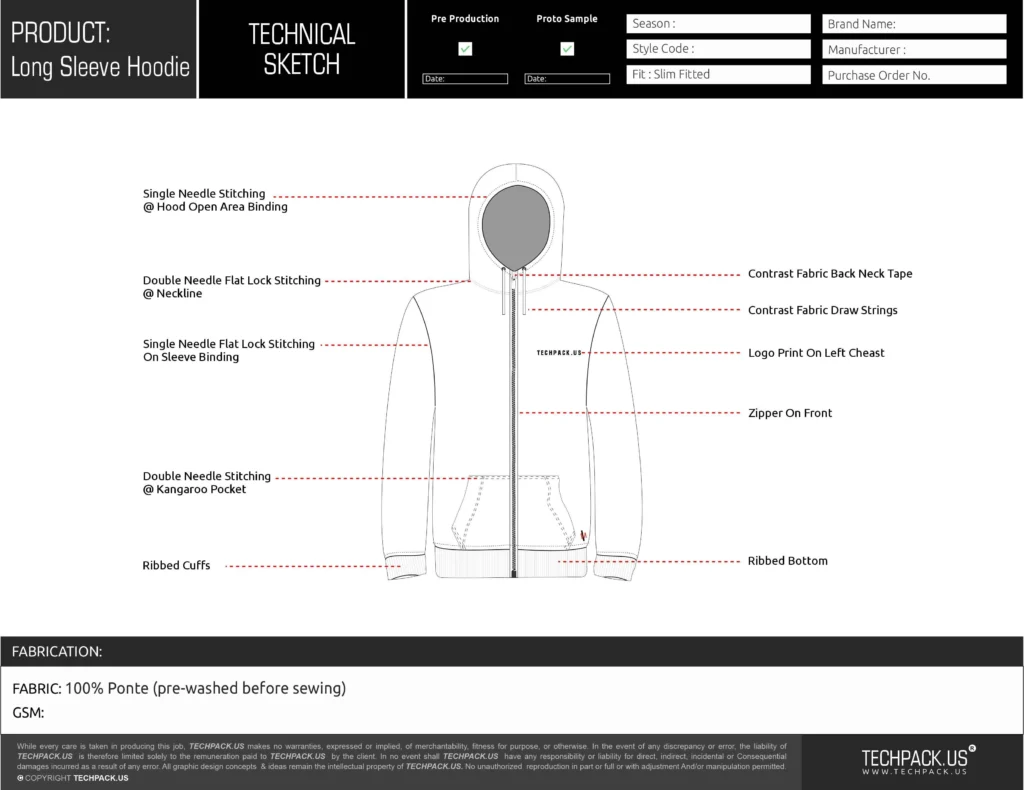

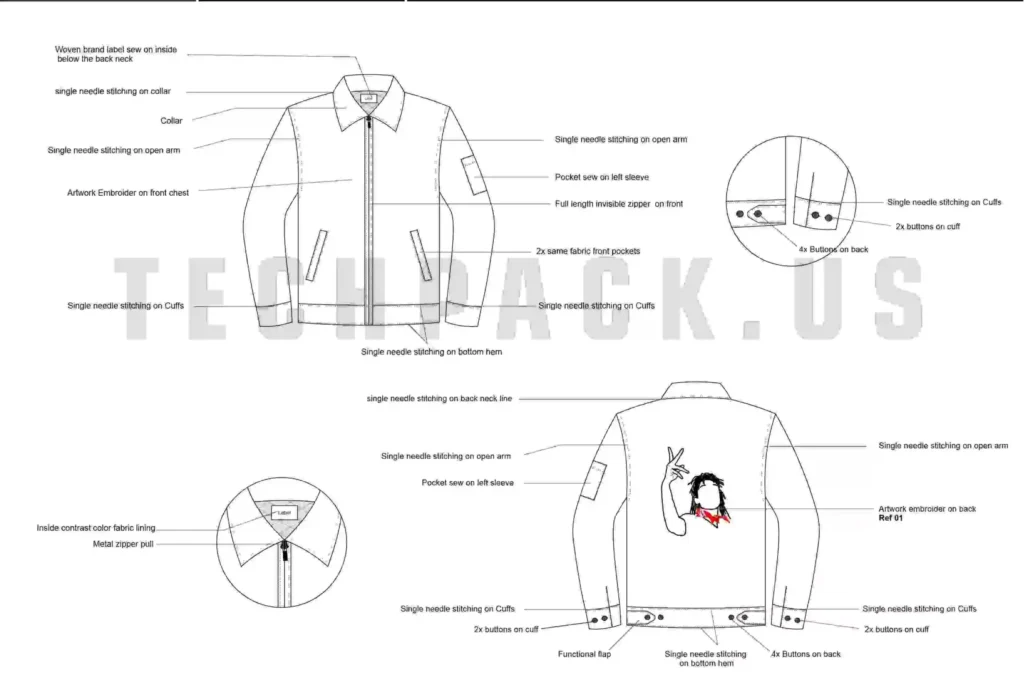

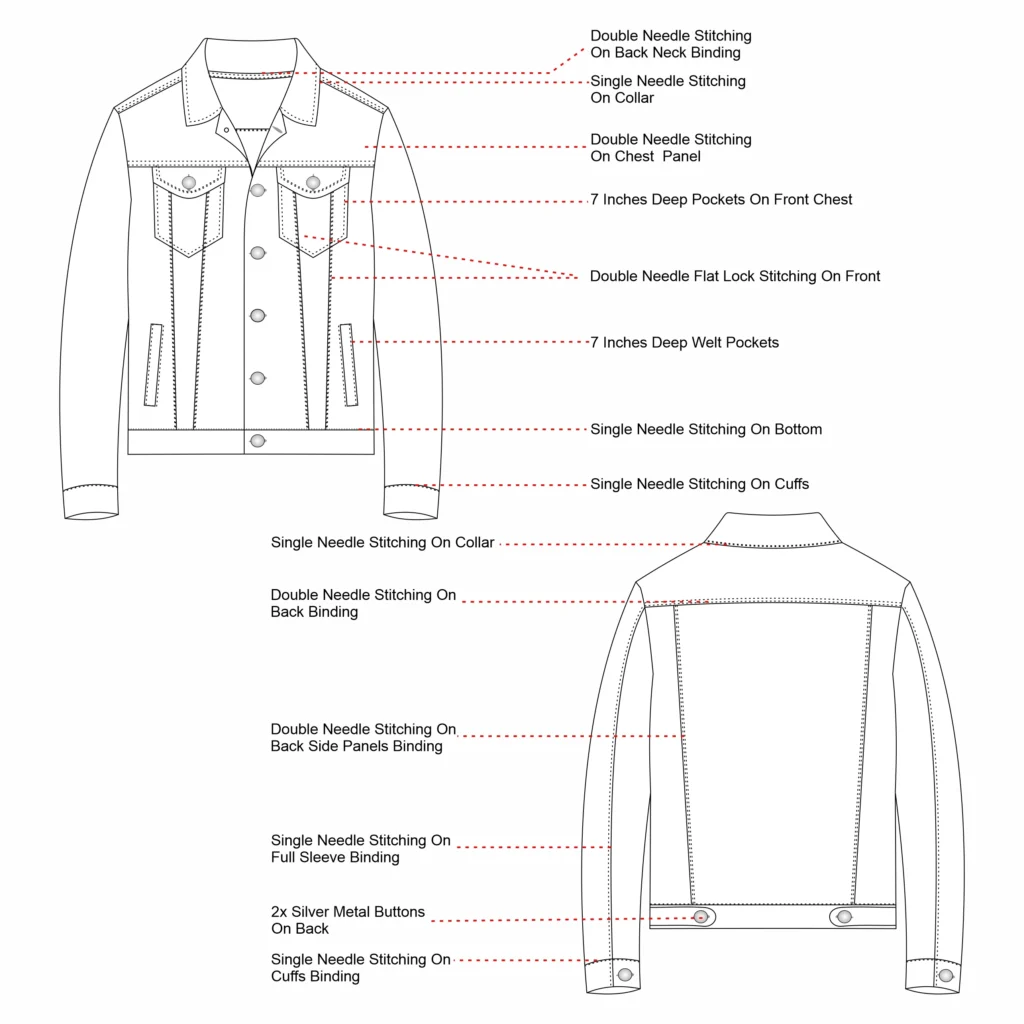

- Flat Sketches: Visual representations of the design. These help manufacturers understand the look.

- Materials List: Details about fabrics and trims. Include information on colors, textures, and any special finishes.

- Measurements: Size specifications for each part of the product. This ensures accuracy in production.

- Construction Details: Instructions on how to assemble the garment. This includes stitching techniques and layering.

- Labels and Tags: Information on branding, care instructions, and size labels. This helps in correct packaging.

- Costing Information: A breakdown of estimated costs. This allows for budget management.

- Production Timeline: Important dates for each stage of the process. This keeps everyone on track.

- Tech Specifications: Technical information about features. This may include details about zippers, buttons, or pockets.

Why We Need Tech packs?

- Clear Communication: Techpacks provide clear details about designs, materials, and construction.

- Efficiency: With a techpacks, teams can work more efficiently. It saves time by providing all necessary information in one place.

- Cost Control: They help in estimating costs accurately. By being specific about materials and processes, companies can avoid unexpected expenses.

- Quality Assurance: Techpacks act as reference points during production. They help maintain quality by ensuring the finished products meet the original design specifications.

- Streamlined Production: They simplify the production process. Manufacturers can produce items more quickly and effectively with all the details outlined.

What Is a Tech Packs Made Of?

It is a crucial document used in the fashion industry.

It contains all the necessary information needed to create a product.

Key components include:

- Technical Drawings: Detailed sketches showing the design from different angles.

- Material Specifications: Information about fabrics, colors, and trims.

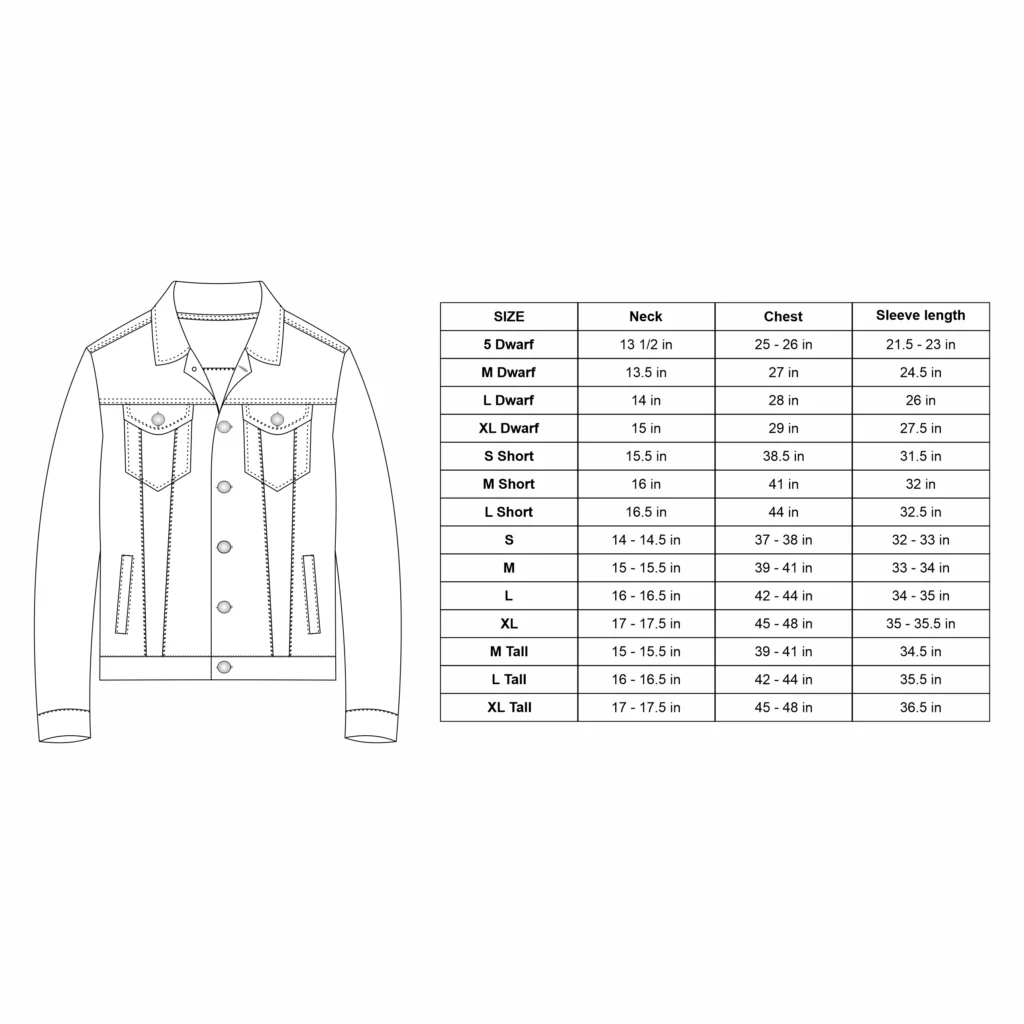

- Size Charts: Measurements for each size to ensure proper fit.

- Construction Details: Instructions on how to assemble the product.

Additionally, it may include:

- Labels and Tags: Specifications for branding and care labels.

- Pricing Information: Cost details and target retail prices.

- Production Timeline: Key deadlines for each stage of production.

Creation of a Techpack

Information Gathering

The first step in creating it is to gather all relevant information about the product. This includes product specifications such as dimensions, materials, colors, and features.

Key points to consider:

- Product Description: A clear description of the item being designed.

- Technical Specifications: Details on materials, measurements, and construction methods.

- Cost Information: Estimated costs for materials and production.

Software and Tools Utilization

Techpacks are often created using specialized software and tools. These platforms help streamline the design process and organize information clearly.

Some commonly used tools include:

- Adobe Illustrator: For creating designs and technical drawings.

- Excel or Google Sheets: For organizing data, costs, and timelines.

- CAD Software: For detailed technical designs and patterns.

Each tool serves a purpose, making it easier to share information with manufacturers.

Proper software ensures accuracy and efficiency in the techpack process.

Using the right technology can significantly improve collaboration and reduce the chance of mistakes.

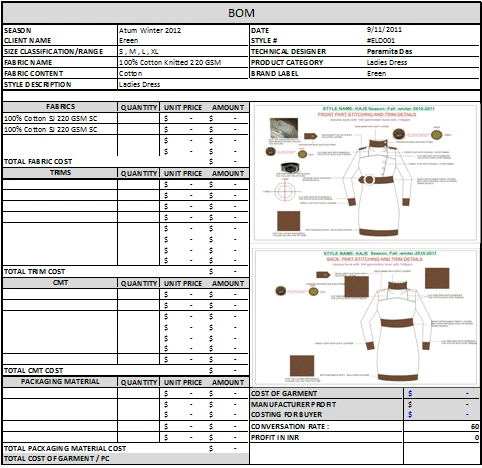

Bill of Materials (BOM)

A Bill of Materials (BOM) is a detailed list of all the materials and components needed to create a product. It serves as a recipe for manufacturers.

A typical BOM includes:

- Item Name: The name of each component.

- Item Number: A unique identification number.

- Quantity: The amount of each item needed.

- Unit of Measure: The measurement for each item, such as pieces or meters.

- Material Type: The specific type of material used.

For example, a simple BOM for a t-shirt tech pack template might look like this:

| Item Name | Item Number | Quantity | Unit of Measure | Material Type |

| Fabric | 001 | 1 | meter | Cotton |

| Thread | 002 | 1 | spool | Polyester |

| Label | 003 | 1 | piece | Woven |

| Button | 004 | 2 | pieces | Plastic |

Creating an accurate BOM helps in planning and production. It ensures that all materials are available when needed.

A well-organized BOM also aids in cost estimation and inventory management. It prevents delays in the production process.

Tech packs Elements

A techpack includes essential components that guide the manufacturing process of a product. Key elements include technical drawings, measurements, specifications, and prototyping procedures.

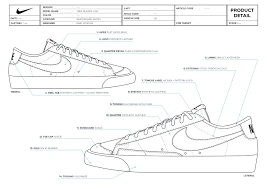

Technical Drawings

It visually represents the product. They show important details such as shapes, fabrics, and stitching. These drawings help manufacturers understand how the final product should look.

- Flat sketches display the product from different angles.

- Detail views highlight specific features like pockets or buttons.

Measurements and Specifications

This section typically includes:

- Size charts that list dimensions for different sizes.

- Fabric types and their attributes, like weight and stretch.

Accurate measurements are vital. They help avoid fit issues and returns.

Specifications also define color codes, trims, and other details that are critical to the design.

Prototyping Procedures

Prototyping procedures explain how to create sample products. This part of the tech-pack outlines the steps needed to test the design before full production.

- Sampling methods may include hand-made samples or digital simulations.

- Testing protocols assess durability and design accuracy.

Industry Adaptations

Fashion and Apparel

In the fashion and apparel industry, techpacks serve as vital tools for designers and manufacturers.

They contain detailed specifications like materials, colors, sizes, and construction methods.

- Materials: Designers specify fabrics and trims, ensuring the manufacturer uses the correct components.

- Measurements: Size charts and garment measurements help avoid fitting issues during production.

- Production Timeline: A clear schedule is essential for on-time deliveries, helping brands meet market demands.

Industrial Design

It assists in the development of products like furniture, tools, and machinery.

They detail materials, dimensions, and finishes to ensure clarity for engineers and manufacturers.

- Material Specifications: Designers list exact materials to avoid variations in texture and strength.

- 3D Models: Many designers include 3D models to visualize the final product, improving communication.

- Assembly Instructions: Clear guidelines help manufacturers assemble complex parts accurately.

This structured approach minimizes misunderstandings and waste, leading to more successful product launches.

Consumer Electronics

- Component Lists: Detailed lists ensure manufacturers source the correct parts, from chips to enclosures.

- Testing Protocols: Instructions for testing help ensure quality and safety standards are met.

- User Instructions: Including user manuals in the techpack aids in creating an informed consumer experience.

Using techpacks in this industry enhances collaboration between design and manufacturing teams, ultimately leading to reliable products that meet user needs.

Case Studies and Examples

Nike’s Techpack Creation Process

Nike uses techpacks to streamline its design and production. Each techpack includes detailed specifications for materials, colors, and sizes. This helps factories understand exactly what is needed for production.

H&M’s Sustainable Techpacks

H&M focuses on sustainability by incorporating eco-friendly materials in their techpacks. They specify organic cotton and recycled fabrics. This approach aids in reducing their environmental impact.

Adidas’ Collaborative Techpacks

Adidas collaborates with designers to create unique techpacks for special collections. They often include artistic elements, such as custom prints. This allows for creativity while ensuring production accuracy.

Key Elements in Successful Techpacks

| Element | Importance |

| Materials | Defines quality and feel |

| Measurements | Ensures proper fit |

| Color Codes | Maintains consistency |

| Construction Details | Guides assembly |

List of Benefits for Using Techpacks

- Reduces production errors

- Speeds up the design process

- Improves communication with manufacturers

- Saves time and costs

These examples show how different brands effectively use techpacks. They highlight the importance of clarity and detail in the design and production stages.

People Also Ask About Tech-pack

Is it necessary to have a tech pack?

Creating it is often essential for fashion designers and manufacturers.

It serves as a blueprint for the production of apparel. A well-made tech-pack minimizes misunderstandings between designers and manufacturers.

What is included in the tech packs?

It often contains:

- Technical sketches: These provide a visual representation of the design.

- Materials list: This details fabrics, trims, and accessories.

- Size specifications: Measurements for garment sizes are crucial.

- Construction details: Information on stitching, finishing, and other processes.

Who uses a tech packs?

Designers rely on them to communicate their ideas clearly. Manufacturers refer to tech packs to understand production requirements.

Benefits of Tech Packs

Here are some key benefits:

- Clear Communication: A tech pack provides detailed information. It helps designers share their ideas with manufacturers without confusion.

- Saves Time: With all specifications outlined, it reduces back-and-forth emails. This speeds up the production process.

- Cost Efficiency: A well-prepared tech packs minimizes mistakes. This helps avoid costly revisions during production.

- Consistent Quality: It ensures that every item produced matches the designer’s vision. This leads to better quality control.

- Easy Updates: If changes are needed, they can easily be made to the tech packs. This keeps everyone on the same page.

- Streamlined Production: It helps manufacturers understand the required materials and techniques. This leads to smoother operations.

HOW MUCH SHOULD A TECH PACKs COST?

Factors that impact cost include:

- Design Complexity: Simple designs require less time and detail. These cost less than more complex styles.

- Number of Pages: More pages cruel more work.. A single-page tech pack may cost less compared to one that includes multiple views.

- Experience of the Designer: Skilled designers may charge more for their expertise. However, their work can often save time and money in production.

- Market Rates: Prices can differ based on where the service is offered. Costs tend to be higher in major cities.

Type of Tech Packs Estimated price

| Basic (1 item, simple) | $70 |

| Intermediate (2-5 items) | $100 – $500 |

| Advanced (multiple items) | $1,000 – $1,500+ |

It’s wise to get quotes from different designers to find the best fit for specific needs and budgets.

Final words

A tech packs is an essential tool for product development. It serves as a detailed guide for designers, manufacturers, and brands.

Creating a tech pack helps ensure that everyone involved understands the project’s needs. This can lead to improved communication and fewer mistakes.

Key components of a tech pack include:

- Design sketches: Visuals that show the concept.

- Materials list: Details about fabrics and other supplies needed.

- Size charts: Measurements for various sizes.

- Production timeline: Clear deadlines for each step.

A well-made tech pack can save time and money. It helps streamline the production process and keeps projects on track.

Using a tech pack can also support quality control. With clear specifications, manufacturers can better meet expectations.

In a competitive market, having a solid tech pack can give brands an edge. It allows them to manage their projects more effectively.