Partnering with the right manufacturer can help you achieve quality, sustainability, and flexibility, ensuring your designs come to life without significant upfront investment.

From small-batch production to custom designs, numerous manufacturers cater specifically to emerging brands, making it easier for you to enter the competitive fashion market.

Understanding the nuances of garment production can set you apart as a startup.

You have options ranging from domestic Clothing Manufacturers for Startups, who often provide quicker turnaround times, to overseas suppliers that might offer lower production costs.

Exploring these choices will empower you to make informed decisions about quality, minimum order quantities, and production timelines.

In this guide, you will discover a range of manufacturers that align with your startup’s values and vision.

Identifying the right fit will elevate your brand and make your entry into the fashion industry a more manageable and rewarding experience.

Choosing the Right Clothing Manufacturers for Startups

Selecting appropriate clothing manufacturers for startups is crucial for your startup’s success.

Understanding your specific needs, assessing the capabilities of potential manufacturers, and deciding between local and overseas production can help ensure you choose the best partner for your business.

Understanding Your Needs

Begin by clearly defining your brand identity and production goals.

Consider the following questions:

- What types of clothing do you want to produce? Are you focusing on active wear, casual wear, or something niche?

- What is your target market? Understanding your audience can influence design, materials, and pricing.

- What is your budget for manufacturing? Include costs for materials, labor, and shipping.

Once you answer these, you can streamline your search for manufacturers who specialize in your garment category.

This precision will help you find partners that can meet your quality and branding requirements.

Read Also : Importance of Shirt Tech Pack

Evaluating Manufacturer Capabilities

After identifying potential Clothing Manufacturers for Startups, assess their capabilities. Here are key factors to consider:

- Experience: Look for a manufacturer with a solid track record in your specific clothing type.

- Quality Control: Ensure they have strict quality assurance processes in place.

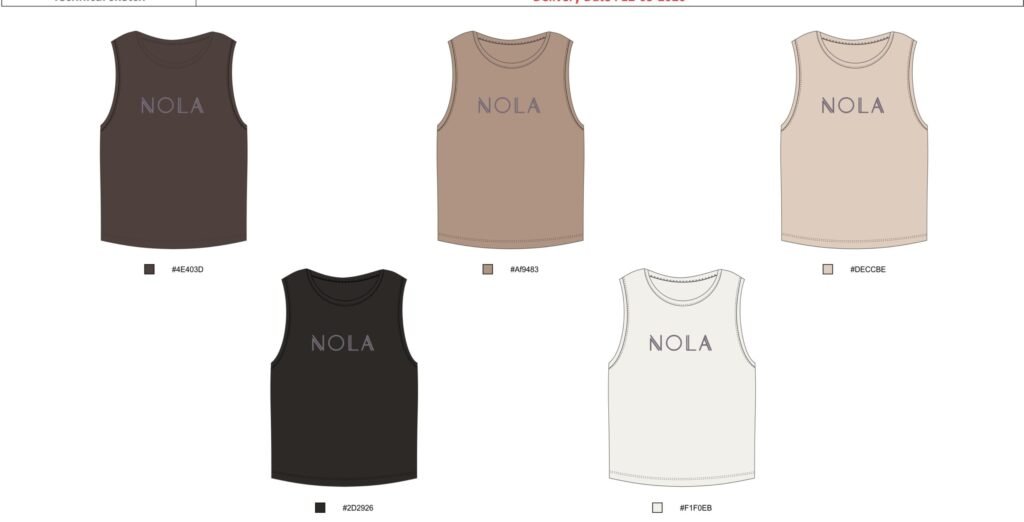

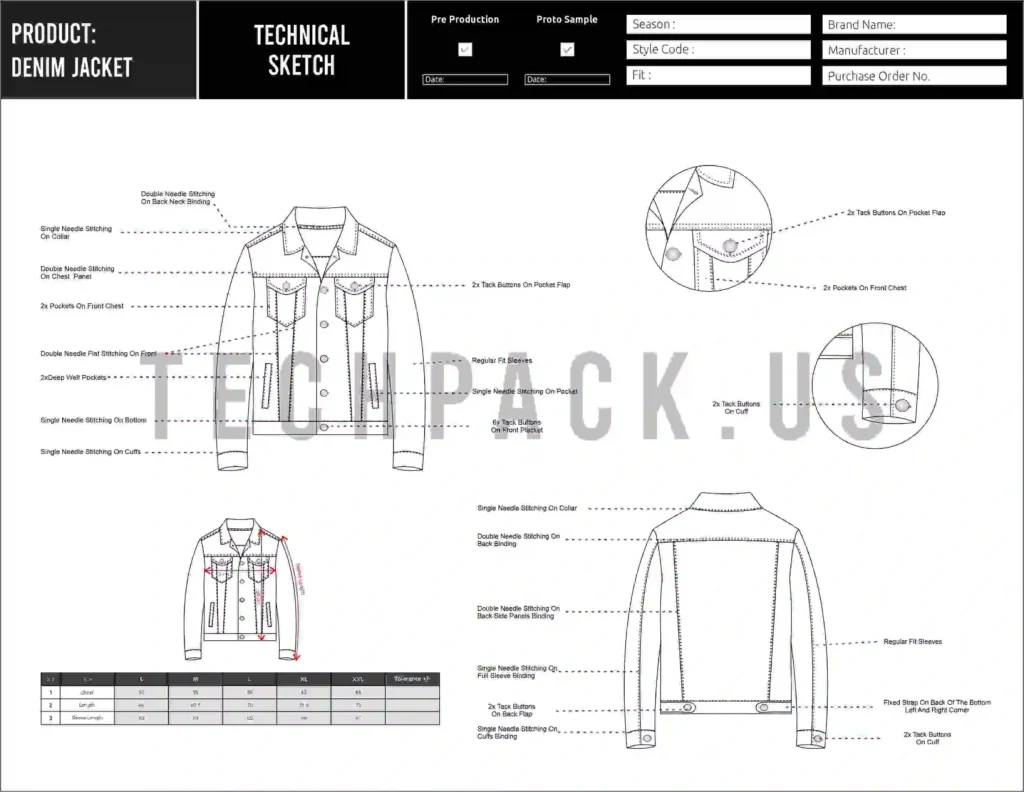

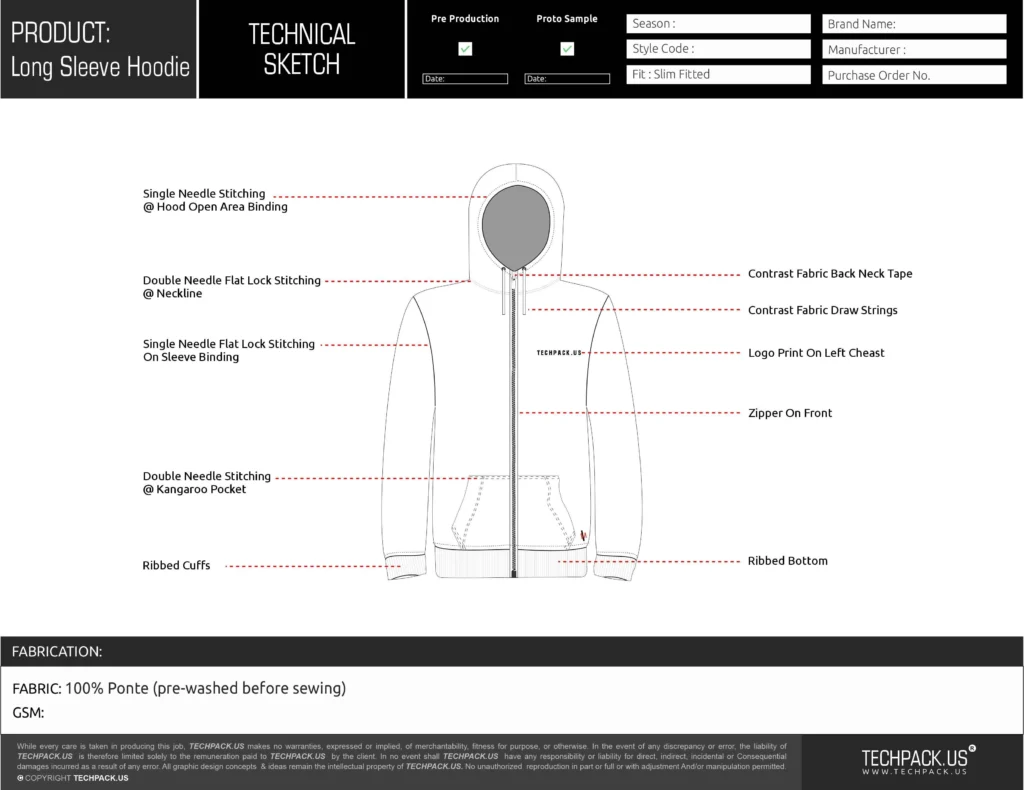

- Customization Options: Confirm that they can handle your design specifications, including sizes and materials.

- Order Minimums: Verify that their minimum order quantities align with your needs, especially as a startup.

You can request samples of previous work to evaluate the quality.

Engaging in discussions about timelines and production capacity can further clarify if they are a suitable partner.

Considering Local vs. Overseas Production

The decision to Clothing Manufacturers for Startups locally or overseas impacts costs, lead times, and communication. Here are some considerations:

- Local Production: Generally offers faster turnaround times and easier communication. It could also appeal to brands emphasizing ethical production practices.

- Overseas Production: Often provides cost advantages due to lower labor costs. However, it may involve longer shipping times and complex logistics.

Evaluate the trade-offs to determine which option aligns with your business strategy.

Factor in potential tariffs and language barriers when considering overseas manufacturers.

Balancing cost and efficiency will be key to your decision-making process.

Building a Relationship with Clothing Manufacturers for Startups

Establishing a strong relationship with your clothing manufacturers is crucial for the success of your startup.

It involves effective communication, setting clear quality standards, and managing production timelines efficiently to ensure a smooth workflow.

Communication and Negotiation

Open lines of communication are essential in your relationship with Clothing Manufacturers for Startups.

Regular updates and feedback help to align both parties’ expectations and can prevent misunderstandings.

- Frequency: Schedule regular check-ins to discuss progress and address any concerns.

- Mode: Use emails for formal communication and instant messaging tools for quicker responses.

Negotiation is equally important. Be clear about your budget, timelines, and specific requirements. Understanding the manufacturer’s processes and limitations will help tailor your negotiations to ensure mutual benefit.

Creating Quality Control Standards

Quality control standards are vital to maintaining consistency in your product. Establishing these standards early can prevent issues down the line.

- Define Standards: Clearly outline the quality expectations for materials, stitching, and finishes.

- Develop Checkpoints: Include production milestones where quality checks will take place, ensuring that both you and the manufacturer are aligned.

- Feedback Loop: Create a system for providing feedback about product quality. This encourages improvement and fosters a sense of partnership.

Regularly revising these standards based on production insights will further enhance quality.

Managing Production Timelines

Timely delivery is a significant factor in maintaining your brand’s reputation. You should manage timelines with precision.

- Set Realistic Deadlines: Collaborate with your manufacturer to establish feasible timelines for production stages, considering current workloads and potential delays.

- Utilize Tools: Implement project management software to track production stages and deadlines. This visibility helps both parties stay informed.

Anticipate potential issues such as sourcing delays or equipment malfunctions. Being proactive allows for timely adjustments to production timelines, thus minimizing disruptions.

Read Also : How to Read a Tech Pack?

Scaling Production

As your startup gains traction, scaling production is essential for meeting increased demand while maintaining quality. Focusing on effective preparation and cost management will ensure your growth is sustainable.

Preparing for Increased Demand

To successfully scale, analyze your sales data to forecast upcoming demand. This will help you determine production rates and inventory needs.

Partnering with clothing manufacturers that specialize in small-batch and large-scale productions is crucial.

Companies like Good Clothing Company and Grade House offer both small-batch and mass-production options, allowing flexibility based on your sales cycle.

Implement technology for efficient order management. Programs that automate inventory tracking will minimize errors and streamline operations.

Establishing strong relationships with manufacturers can facilitate quicker turnaround times during peak demand.

Pricing and Cost Strategies

Understanding your pricing structure is vital for scaling effectively. Calculate all costs involved in production, including materials, labor, and overhead.

This ensures you set a competitive price that covers your expenses while attracting customers.

Negotiate with manufacturers for bulk pricing discounts as you scale up production. Establishing contracts with suppliers can also lock in pricing, protecting you from fluctuations.

Consider implementing tiered pricing for different quantities.

This strategy can encourage larger orders from retailers or bulk buyers, boosting your revenue while keeping manufacturing costs lower.

Aim for a pricing model that balances profitability and customer attraction to support your growth trajectory.

Sustainability and Ethical Considerations

When starting a clothing line, understanding sustainability and ethical practices is crucial.

You need to prioritize eco-friendly Clothing Manufacturers for Startups and ethical labor to foster a responsible brand image and attract conscious consumers.

Eco-Friendly Manufacturing Practices

Your choice of Clothing Manufacturers for Startups can significantly impact the environment.

Look for manufacturers that implement eco-friendly practices such as using sustainable materials and water-efficient techniques.

- Organic Fabrics: Select materials like organic cotton, which reduce chemical use during cultivation.

- Recycled Materials: Consider manufacturers that use recycled polyester or other fabrics to minimize waste.

- Waste Management: Ensure the manufacturer has a waste reduction plan. This includes recycling scrap fabric and reducing water usage in the manufacturing process.

Sustainable manufacturing doesn’t just protect the environment it can also enhance your brand appeal and meet growing consumer demand for green products.

Ethical Labor Practices

Ethical labor practices are vital for building a reputable clothing brand.

It’s essential to engage with Clothing Manufacturers for Startups that uphold fair labor standards and promote worker rights.

- Fair Wages: Ensure that workers are paid a living wage, which can significantly improve their quality of life.

- Safe Working Conditions: Look for factories that prioritize safety and health regulations.

- No Child Labor: Partner with manufacturers that commit to ethical practices, avoiding any form of exploitation.

By prioritizing ethical labor, you not only contribute to social betterment but also enhance your brand’s integrity and trustworthiness in the market.